Z4 type expansion joint sleeveCompared with the Z4 type, the Z2 type expansion coupling sleeve has a long joint surface and high centering accuracy. It is used for rotation accuracy...

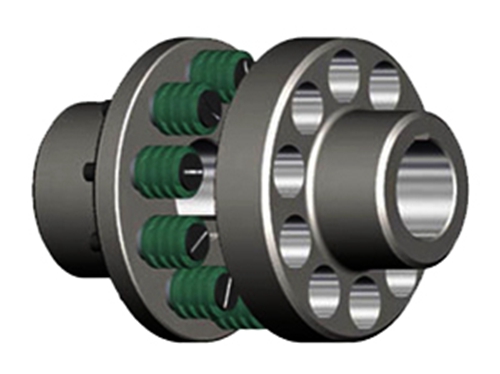

Z4 type expansion joint sleeveCompared with the Z4 type, the Z2 type expansion coupling sleeve has a long joint surface and high centering accuracy. It is used for rotation accuracy... LT elastic sleeve pin couplingLT elastic sleeve pin coupling is a non-metal elastic element flexible coupling, and its structure is similar to the convex...

LT elastic sleeve pin couplingLT elastic sleeve pin coupling is a non-metal elastic element flexible coupling, and its structure is similar to the convex... Elastic sleeve pin coupling for pumpElastic sleeve pin couplings for pumps generally use flexible couplings for the purpose of transmitting power and compensating...

Elastic sleeve pin coupling for pumpElastic sleeve pin couplings for pumps generally use flexible couplings for the purpose of transmitting power and compensating... LLA tire couplingLLA tire couplings are made into non-standard couplings according to special needs. When overloaded,...

LLA tire couplingLLA tire couplings are made into non-standard couplings according to special needs. When overloaded,... GY, GYS, GYH type couplingThe surface roughness of GY, GYS, GYH couplings refers to the small spacing and...

GY, GYS, GYH type couplingThe surface roughness of GY, GYS, GYH couplings refers to the small spacing and...In a similar diaphragm rubber coupling structure, in order to minimize the reaction moment of each group of metal diaphragms under larger angular bending deformation, the two groups of metal diaphragms are set at both ends and expanded as much as possible. The spacing between the groups of diaphragms.

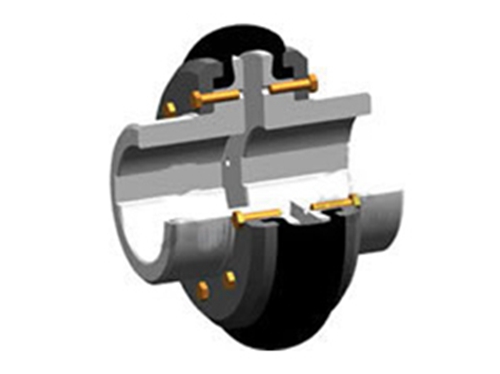

Due to manufacturing and installation errors, load-bearing deformation, thermal deformation, and sinking of the base, the two shafts connected by the plum blossom elastic coupling will have a certain axial, angular, and radial offset between the axes.

The inherent hazards that exist before the hoisting machinery is put into use are mainly divided into three stages. The first is the selection phase of the crane. The parameters of the hoisting machinery are the indicators of the working performance of the hoisting machinery and the basis for the design. The basis of which type of lifting equipment is used in the operation.

When the crane is working, the misalignment of the coupling between the reducer and the motor of the hoisting mechanism and the luffing mechanism, or the shaft between the two due to excessive installation errors, will cause the vibration of the machine, the wear of the bearing and the shaft Deflection and deformation will cause the high-speed shaft of the reducer to break in serious cases, which poses a great threat to the normal operation of the system. From the recent several accidents of the crane reducer shaft broken, it may be caused by such factors. of.

Because the shaft of the induced draft fan and the motor are not concentric, or there is no gap between the induced draft fan and the motor coupling, it will also cause severe vibration of the bearing seat and the motor.

The elastic coupling can compensate for the axial offset, radial offset or angular offset of the shafting axis during operation to ensure the operation of the shafting equipment.

There are relatively many types of cable reels, and the more common ones are counterweight, hysteresis, frequency conversion, torque, etc.

Due to bearing misalignment, the load distribution of each bearing and the dynamic characteristics of the bearing change, which affects the stability of the entire rotor-bearing system;