【一】The influence of different connection modes of rubber blocks on the radial stiffness characteristics of the coupling

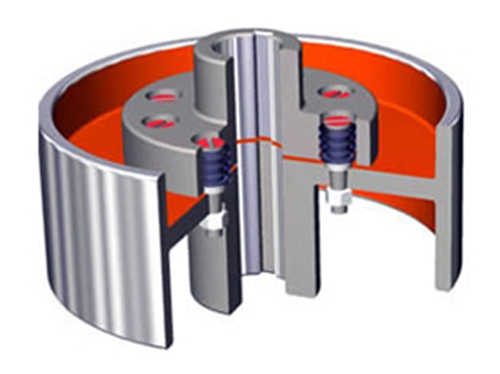

In a similar diaphragm rubber coupling structure, in order to minimize the reaction moment generated by each group of metal diaphragms under larger angular bending deformation, the two sets of metal diaphragms are arranged at both ends and enlarged as much as possible. The spacing between the groups of diaphragms.As the total length of the plum blossom elastic coupling has been determined, the positions of the diaphragm groups at both ends are easily determined; given the torque load and other requirements, the structural parameters of the diaphragm are also quickly determined.Therefore, it is the main task to consider the connection between the middle rubber block structure and the two end diaphragm groups.

There are two ways to connect the rubber block to the diaphragm group at both ends: the end connection type and the radial connection type.Corresponding to these two connection methods, when the coupling transmits torque, the shear stress and tangential deformation of the rubber block also have two different forms, namely, the two ends are relatively twisted and the inner and outer diameters are relatively twisted.

Comparing the torsional stiffness relational expressions of the end connection type rubber block and the radial connection type rubber block, it can be seen that when the structure size of the rubber block is the same, the end connection type rubber block has a greater torsional stiffness than the radial connection type rubber block. A lot (close to 2 times).Therefore, under the same torque, the torsional deformation of the end-connected rubber block is much smaller, and the corresponding torsional stress is much smaller.

For the end-connected rubber block structure, when it is subjected to torque, the main deformation of the rubber block is shear deformation and the deformation is small, and then subjected to the same given radial displacement, the rubber block is still sheared and deformed. The force will be smaller.The radially connected rubber block structure, when subjected to torque, is mainly sheared and deformed greatly, but when subjected to radial displacement, some rubber blocks will show compression deformation.Because the compressive elastic modulus of the rubber material is greater than its shear elastic modulus, and the stress of the rubber block during torsional deformation is greater, the reaction force generated at this time is greater.Therefore, the radial reaction force of the end connection type rubber block structure is smaller than the radial reaction force of the radial connection type rubber block structure.

When bearing the axial displacement after bearing the torque load, the force trend of the two connection structures is opposite to the trend when bearing the radial displacement, that is, the end connection type rubber block is compressed, and the radial connection type rubber block is subjected to compression. Shear, therefore, the axial rigidity of the radial connection type rubber block structure is less than the axial rigidity of the end connection type rubber block structure.

In the analysis of radial stiffness characteristics, the rated torque is first applied to the coupling in one load step, and then in two load steps, a specified radial displacement or shaft is applied to the coupling while keeping the torque constant. To displacement.

Through the analysis and research of the couplings with different connection structures of the rubber blocks, it can be seen that the radial stiffness of the end and connection structure is much lower than that of the radial connection type structure, and the axial stiffness of the end and connection type structure is radial. Greater than the axial rigidity of the connection type structure.In practical applications, the radial rigidity and axial rigidity of the coupling are required to be within an appropriate range, and the realization of the radial rigidity is much more difficult than the axial rigidity.The results show that the radial stiffness of the radial connection type coupling is obviously too large, and the radial stiffness of the end connection type coupling is much lower, and its axial stiffness is slightly larger than that of the radial connection type (but still able to Meet the technical requirements), so the overall performance of the end and connection type is better.

The possible situations of the crane in the working process will be analyzed separately: First, when the hoisting mechanism is fully loaded with goods, because the coupling between the motor and the reducer falls off, the hoisting mechanism loses power and the goods are free from a higher point. When falling, the brakes are not working. In the model, the right brake wheel rotates at a high speed under the drive of the cargo. At this time, the inertial force generated by the brake wheel may make the high-speed shaft fail; second, the whole machine runs normally, but due to installation errors. The misalignment of the shaft or the motor shaft and the shaft of the reducer causes an accessory force to be generated at the left end of the high speed shaft of the reducer, and with the rotation of the shaft, the direction of this force is alternating. If it is used for a long time, it will cause fatigue Fracture, the fatigue failure analysis will not be analyzed here, and it will be studied from the combination of bending and torsion; third, the whole machine works normally, due to an emergency, the two high-speed axle brakes brake at the same time, which is added to the brake wheel. The torque is very large, and the high-speed shaft of the reducer may fail due to insufficient torsional strength; fourth, when the misalignment and two brakes are simultaneously braked, the high-speed shaft may also fail.

[XNUMX] Problems in the use of cranes

The use of cranes speeds up the pace of urban development, which reduces the difficulty of construction and improves construction efficiency.At the same time, how to maximize the benefits of cranes is the direction of relevant practitioners' efforts.Gear couplings should use cranes to reduce hidden dangers in the construction process. Every staff member who has worked hard for the development of the city will lay a solid foundation for the development and construction of a beautiful city.

1. Product quality issues

As my country still has a big gap with developed countries such as Europe and America in some technical aspects, there are still problems or defects in the quality of products.For example, the selection of crane materials, performance stability, service life, frequency of failures, etc., will bring huge hidden dangers to construction.How to optimize the design structure of the crane to make the product performance more stable and product quality is one of the problems that need to be solved next.

2. Product installation problems

Appropriate installation and disassembly of the crane is required before and after using the crane.

The degree of installation and disassembly determines the working capacity and service life of the crane.The correct installation can make the crane more effective and serve the construction project well.If there is an installation error, even a small component problem, it may affect the sensitivity and working coefficient of the machine.If an installation error occurs in a key part, the consequences will be disastrous.When disassembling, how to do a good job of maintenance of the equipment, as much as possible to reduce damage and extend the service life of the crane is also an important aspect.However, there are many unqualified employees in the industry, which increases the risk factor in the use of cranes.

LXJ star elastic couplingThe standard of LXJ star elastic coupling is JB/T 10466-2004.Star couplings are sometimes mistaken for...

LXJ star elastic couplingThe standard of LXJ star elastic coupling is JB/T 10466-2004.Star couplings are sometimes mistaken for... Rubber couplingStructural features and advantages of rubber couplings: compressible elastomer design, easy assembly, performance,...

Rubber couplingStructural features and advantages of rubber couplings: compressible elastomer design, easy assembly, performance,... JMI diaphragm couplingThe JMI diaphragm coupling belongs to the JM series of diaphragm couplings that can compensate the driving machine and the driven machine...

JMI diaphragm couplingThe JMI diaphragm coupling belongs to the JM series of diaphragm couplings that can compensate the driving machine and the driven machine... Z8 type expansion joint sleeveThe characteristics of the Z8 type expansion coupling sleeve: Z8 type locking coupling disc Z8 type expansion sleeve is suitable for shafts and shaft parts...

Z8 type expansion joint sleeveThe characteristics of the Z8 type expansion coupling sleeve: Z8 type locking coupling disc Z8 type expansion sleeve is suitable for shafts and shaft parts... LTZ elastic sleeve pin couplingThe LTZ elastic sleeve pin coupling has a relatively simple structure, easy to manufacture, no lubrication, no need to...

LTZ elastic sleeve pin couplingThe LTZ elastic sleeve pin coupling has a relatively simple structure, easy to manufacture, no lubrication, no need to...