FCL type elastic sleeve pin couplingFCL type elastic sleeve pin coupling has the performance of compensating the relative deviation of the two shafts, suitable...

FCL type elastic sleeve pin couplingFCL type elastic sleeve pin coupling has the performance of compensating the relative deviation of the two shafts, suitable... ML plum blossom couplingML type plum blossom coupling has simple structure, small radial size, light weight, small moment of inertia, suitable for...

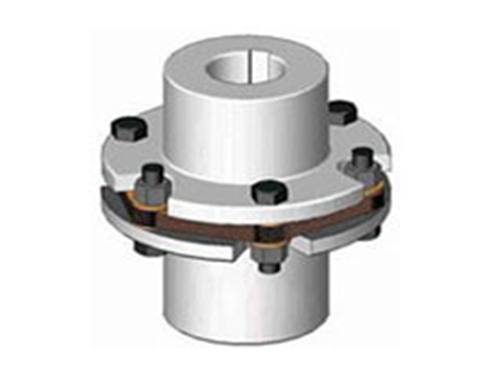

ML plum blossom couplingML type plum blossom coupling has simple structure, small radial size, light weight, small moment of inertia, suitable for... Stainless steel elastic coupling JZM typeThe stainless steel elastic coupling JZM type is a large torque diaphragm coupling for the shaft connection of heavy machinery and equipment...

Stainless steel elastic coupling JZM typeThe stainless steel elastic coupling JZM type is a large torque diaphragm coupling for the shaft connection of heavy machinery and equipment... GR-shaped coupling elastic bodyGR-shaped coupling elastic body is one of the main products produced by our company. It is widely used for rolling...

GR-shaped coupling elastic bodyGR-shaped coupling elastic body is one of the main products produced by our company. It is widely used for rolling... ZLL elastic pin gear couplingThe basic parameters and important measurement of ZLL elastic pin gear coupling are used for a lot of non-metallic materials...

ZLL elastic pin gear couplingThe basic parameters and important measurement of ZLL elastic pin gear coupling are used for a lot of non-metallic materials...The requirement for the exchangeability of the essential parts of the drum gear coupling is worthy of our attention: the parts of each specification of the drum gear coupling can be exchanged. If one of them is damaged, it can be replaced with a single spare part. All are changed, which saves maintenance time and is convenient for use

The plum blossom elastic coupling has the ability to compensate, and is suitable for working conditions where there is an offset between the two axes, and has cushioning and shock absorption properties.The coupling does not need to be lubricated and can work in dusty and humid conditions. The structure is simple and the maintenance is convenient. However, it needs to be moved when changing the elastic element.

In the process of using the crane, the user company should require the manufacturer to provide the corresponding qualification certificate. The manufacturer should also provide the electrical schematic diagram, general diagram, main force-bearing component diagram, installation, use and maintenance instructions of the construction crane, etc., and the maintenance of the crane. Maintenance contracts and inspection reports should also be in place.

Wear is a common defect of gear couplings. During operation, due to relative sliding between the inner and outer gear rings of the coupling, this is the basic cause of wear.

For rail-mounted gantry cranes, plum-shaped elastic couplings have common cable drum failures as follows: cable drum loose cable failure, drum mechanical failure, drum electrical circuit failure, and so on.

Because the shaft of the induced draft fan and the motor are not concentric, or there is no gap between the induced draft fan and the motor coupling, it will also cause severe vibration of the bearing seat and the motor.

Improving the reform and innovation of the equipment structure by the operating unit, and carrying out on-site operation guidance with innovation is an important means to increase the participation of bridge projects, and how to improve the efficiency of equipment operation has become the key.

In a similar diaphragm rubber coupling structure, in order to minimize the reaction moment of each group of metal diaphragms under larger angular bending deformation, the two groups of metal diaphragms are set at both ends and expanded as much as possible. The spacing between the groups of diaphragms.

As a widely used type of crane, cranes can improve workshop productivity.As a large-scale lifting equipment, its internal structure is very complicated, which requires attention to daily inspection and maintenance work, to find problems in crane inspection, and to propose relevant countermeasures.