【一】, the cause of the fault causing the fan vibration

Analyzing the phenomenon and causes of fan failures, there are rules to follow. Generally speaking, there are the following types:

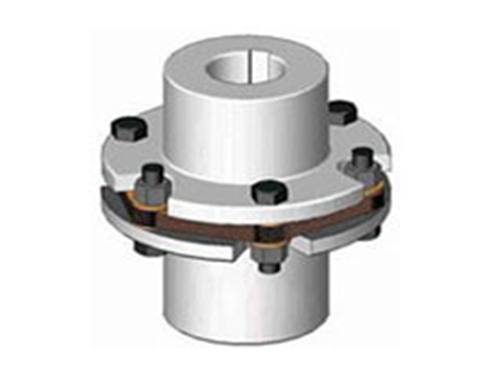

(1) Design reason: The design of the fan is generally designed according to the use environment, temperature, air volume, wind pressure, medium, etc. of the fan, and some companies do not select the model according to these factors, resulting in the following factors: Improper design, poor dynamic characteristics, vibration during operation of the plum elastic coupling; unreasonable structure, stress concentration; design working speed close to or falling into the critical speed zone; inaccurate calculation of thermal expansion, resulting in poor thermal alignment.

(2) Manufacturing reasons: The quality requirements of the fan manufacturer also affect the operation of the fan, such as: poor parts processing and manufacturing, insufficient precision; poor parts material, insufficient strength, manufacturing defects; rotor dynamic balance does not meet technical requirements, etc.

(3) Reasons for installation and maintenance: The installation accuracy requirements of the fan play a vital role in the operation of the fan. If the installation accuracy does not meet the installation requirements, it will have a destructive effect on the operation of the fan.During the installation of the fan, there are the following influencing factors, such as: improper mechanical installation, misalignment of parts, large preload; poor shaft alignment; improper adjustment of machine geometric parameters (such as fit clearance, interference, and relative position); The improper placement of the rotor for a long time has changed the accuracy of dynamic balance; the failure to check and repair in accordance with the regulations has destroyed the original matching properties and accuracy of the machine.

风机的安装标准是:抽风机纵向、横向中心线偏差为12mm。抽风机标高偏差为±2mm。抽风机水平度公差为0.2/1000。底座标高偏差为±2mm。底座纵向、横向中心线偏差为士2mm。两底座的中心距离偏差为±2mm。两底座上表面应在同一水平面上,其高低差不得大于0.5mm。底座横向水平度公差为0.2/1000;纵向水平度公差为0.1/1000。

(4) Reasons for operation and operation: During the use of the fan, the maintenance and maintenance of the fan plays a decisive role in the operation quality of the fan.Such as: process parameters (such as medium temperature, pressure, flow, load, etc.) deviate from the design value, the machine operating conditions are abnormal; the machine runs at excessive speed or overload, which changes the working characteristics of the machine; poor lubrication or cooling; Partial damage or fouling of the rotor; improper operation during start-up and shutdown or speed-up/down, uneven thermal expansion, or staying in the critical zone for too long, etc.

(5) Reasons for machine deterioration: general equipment has a limited life when in use, and the performance of the equipment will deteriorate when it reaches the end of life.The same is true for fans, such as: long-term operation, the rotor deflection increases or the dynamic balance deteriorates; the rotor is partially damaged, peeled off or cracked; parts are worn, pitted or corroded, etc.; the mating surface is stressed and the interference is insufficient Or loosening, etc., destroying the matching properties and accuracy; the machine foundation is not uniformly settled, and the machine shell is deformed.

The possible situations of the crane in the working process will be analyzed separately: First, when the hoisting mechanism is fully loaded with goods, because the coupling between the motor and the reducer falls off, the hoisting mechanism loses power and the goods are free from a higher point. When falling, the brakes are not working. In the model, the right brake wheel rotates at a high speed under the drive of the cargo. At this time, the inertial force generated by the brake wheel may make the high-speed shaft fail; second, the whole machine runs normally, but due to installation errors. The misalignment of the shaft or the motor shaft and the shaft of the reducer causes an accessory force to be generated at the left end of the high speed shaft of the reducer, and with the rotation of the shaft, the direction of this force is alternating. If it is used for a long time, it will cause fatigue Fracture, the fatigue failure analysis will not be analyzed here, and it will be studied from the combination of bending and torsion; third, the whole machine works normally, due to an emergency, the two high-speed axle brakes brake at the same time, which is added to the brake wheel. The torque is very large, and the high-speed shaft of the reducer may fail due to insufficient torsional strength; fourth, when the misalignment and two brakes are simultaneously braked, the high-speed shaft may also fail.

[Two], gantry crane installation process

Under the social background of social economic growth, my country’s modern industry has also achieved development. In order to better meet the needs of contemporary society for industrial construction, the gear coupling has continuously introduced modern equipment in industrial production, and among many equipment , Bridge gantry crane is one of them.Because the bridge gantry crane has higher requirements in the running mode, it is important to do its inspection work well.However, due to many factors, there are still some problems in the inspection process that need to be improved, so it is necessary to pay full attention to its inspection work.

The quality of the installation has a great influence on the normal use of the bridge gantry crane, and the unqualified installation of the equipment can easily lead to accidents.In the installation process of the bridge gantry crane, there are mainly the following problems: First, the equipment foundation does not meet the requirements.Based on the work content of the bridge gantry crane, it usually has a higher load-bearing capacity requirement, and the equipment itself is also large. Therefore, for the normal use of the equipment, the level and stability of the ground should be as stable as possible during installation. .However, in the actual installation process, due to the lack of awareness of the installer or the craftsmanship does not meet the requirements, the equipment was not installed strictly in accordance with the relevant standards, which caused the equipment to fail to operate normally after the installation was completed.Therefore, in the equipment installation process, the relevant departments must not only install the reasonable design during the design process, but also strictly take the design as the basis, and carry out the installation work. Second, the distance between the moving parts and the power line is not up to standard.According to relevant regulations and standards, no part of the bridge gantry crane should be in contact with the live power line during use, otherwise it will not only easily damage the equipment, but also seriously threaten the personnel of the staff.Third, the installation is not in place or the switch is missing.The weight limiter plays a very important role in the operation of the bridge gantry crane. Once the equipment exceeds the limited weight range during the operation of the equipment, the crane will automatically cut off the power supply.However, in actual installation, there is a situation that the weight limiter is not installed properly, resulting in the failure of the weight limit protection function.In addition, the lack of switches is also a common problem, causing the emergency power off switch to not be able to emergency power off when it fails, and it cannot achieve the protection of equipment and personnel.To avoid these problems, the equipment must be installed in strict accordance with the standards, and the debugging work must be fully done so that all components can be used normally.

LXT star elastic couplingThe elastic element in the Ever-PowerLXT star elastic coupling is engineering plastic, because the engineering plastic...

LXT star elastic couplingThe elastic element in the Ever-PowerLXT star elastic coupling is engineering plastic, because the engineering plastic... Stainless steel elastic coupling JZM typeThe stainless steel elastic coupling JZM type is a large torque diaphragm coupling for the shaft connection of heavy machinery and equipment...

Stainless steel elastic coupling JZM typeThe stainless steel elastic coupling JZM type is a large torque diaphragm coupling for the shaft connection of heavy machinery and equipment... Plum elastic couplingThe plum blossom elastic coupling has a high sales volume in the market, and it is a new product that has attracted people's attention...

Plum elastic couplingThe plum blossom elastic coupling has a high sales volume in the market, and it is a new product that has attracted people's attention... Z19A type expansion joint sleeveZ19A type expansion coupling sleeve is the main product of our company, which has attracted much attention in the industry. Z...

Z19A type expansion joint sleeveZ19A type expansion coupling sleeve is the main product of our company, which has attracted much attention in the industry. Z... LXP star couplingLXP star coupling is made of engineering plastics as elastic elements, suitable for connecting two coaxial cables...

LXP star couplingLXP star coupling is made of engineering plastics as elastic elements, suitable for connecting two coaxial cables...