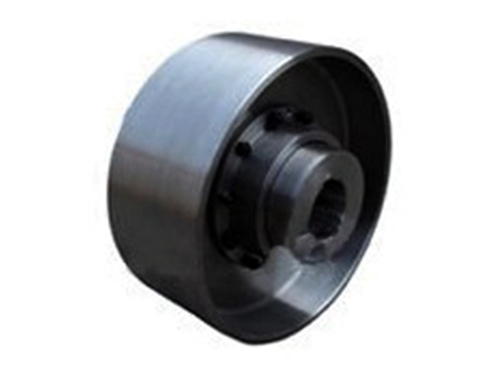

GY, GYS, GYH typeCouplingThe surface roughness refers to the small spacing and small peak and valley unevenness of the processed surface.The distance (wave distance) between the two wave crests or two wave troughs is very small (below 1mm), which is difficult to distinguish with the naked eye, so it belongs to the microscopic geometric shape error.The smaller the surface roughness, the smoother the surface.The surface roughness has a great influence on the performance of mechanical parts.

|

model

|

Nominal torque Tn(Nm)

|

Allowable speed [n]r/min

|

Diameter of shaft hole

|

Length of shaft hole

|

D

|

b

|

b1

|

S

|

Moment of inertia Kg.m2

|

Mass kg

|

|

|

d1 d2

|

Y type

|

J1 type

|

|||||||||

|

GY1

GYS1 GYH1 |

25

|

12000

|

12,14

|

32

|

27

|

80

|

26

|

42

|

6

|

0.0008

|

1.16

|

|

16,18,19

|

42

|

30

|

|||||||||

| GY2 GYS2 GYH2 |

63 | 1000 | 16,18,19 | 42 | 30 | 90 | 28 | 44 | 6 | 0.0015 | 1.72 |

| 20,22,24 | 52 | 38 | |||||||||

| 25 | 62 | 44 | |||||||||

| GY3 GYS3 GYH3 |

112 | 9500 | 20,22,24 | 52 | 38 | 100 | 30 | 46 | 6 | 0.0025 | 2.38 |

| 62 | 44 | ||||||||||

| 25,28 | |||||||||||

| GY4 GYS4 GYH4 |

224 | 9000 | 25,28 | 62 | 44 | 105 | 32 |

48

|

6 | 0.003 | 3.15 |

| 30,32,35 | 82 | 60 | |||||||||

| GY5 GYS5 GYH5 |

400 | 8000 | 30,32,35,38 | 82 | 60 | 120 | 36 | 52 | 8 | 0.007 | 5.43 |

| 40,42 | 112 | 84 | |||||||||

| GY6 GYS6 GYH6 |

900 | 6800 | 38 | 82 | 60 | 140 | 40 | 56 | 8 | 0.015 | 7.59 |

| 40,42,45,48,50 | 112 | 84 | |||||||||

| GY7 GYS7 GYH7 |

1600 | 6000 | 48,50,55,56 | 112 | 84 | 160 | 40 | 56 | 8 | 0.031 | 13.1 |

| 60,63 | 142 | 107 | |||||||||

| GY8 GYS8 GYH8 |

3150 | 4800 | 60,63,65,70,71,75 | 142 | 107 | 200 | 50 | 68 | 10 | 0.103 | 27.5 |

| 80 | 172 | 132 | |||||||||

| GY9 GYS9 GYH9 |

6300 | 3600 | 75 | 142 | 107 | 260 | 66 | 84 | 10 | 0.319 | 47.8 |

| 80,85,90,95 | 172 | 132 | |||||||||

| 100 | 212 | 167 | |||||||||

| GY10 GYS10 GYH10 |

10000 | 3200 | 90,95 | 172 | 132 | 300 | 72 | 90 | 10 | 0.720 | 82.0 |

| 100,110,120,125 | 212 | 167 | |||||||||

|

GY11

GYS11 GYH11 |

25000 | 2500 | 120,125 | 212 | 167 | 380 | 80 | 98 | 10 | 2.278 | 162.2 |

| 130,140,150 | 252 | 202 | |||||||||

| 160 | 302 | 242 | |||||||||

| GY12 GYS12 GYH12 |

50000 | 2000 | 150 | 252 | 202 | 460 | 92 | 112 | 12 | 5.923 |

285.6

|

| 160,170,180 | 302 | 242 | |||||||||

| 190,200 | 352 | 282 | |||||||||

| GY13 GYS13 GYH13 |

100000 | 1600 | 190,200,220 | 352 | 282 | 590 | 110 | 130 | 12 | 19.978 | 611.9 |

| 240,250 | |||||||||||

| 410 | 330 | ||||||||||

Brake wheel

The quality sales of brake wheels produced by our company...

Brake wheel

The quality sales of brake wheels produced by our company...

KC series sprocket coupling

KC series sprocket coupling is the use of public...

KC series sprocket coupling

KC series sprocket coupling is the use of public...

Z6 type expansion coupling sleeve

The main...

Z6 type expansion coupling sleeve

The main...

SWC_WH coupling

Universal coupling big features...

SWC_WH coupling

Universal coupling big features...