Z16 type expansion joint sleeveThe variety and quality of Z16 expansion joint sleeves are stable.The company's equipment, technology...

Z16 type expansion joint sleeveThe variety and quality of Z16 expansion joint sleeves are stable.The company's equipment, technology... SWP_A universal couplingSWP_A universal coupling has large angle compensation capability and large axial displacement compensation capability, back...

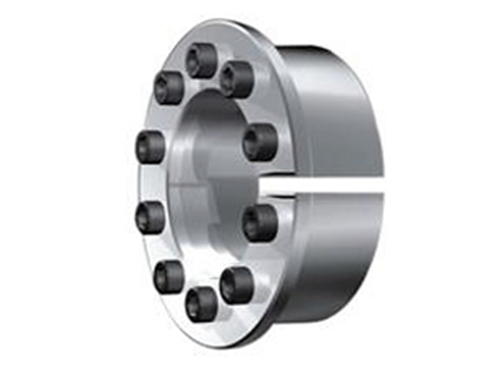

SWP_A universal couplingSWP_A universal coupling has large angle compensation capability and large axial displacement compensation capability, back... Z12C type expansion joint sleeveThe Z12C type expansion coupling sleeve is suitable for the connection of the shaft and the parts on the shaft to transmit torque, axial force...

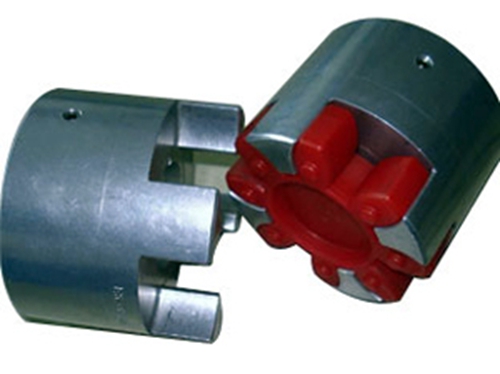

Z12C type expansion joint sleeveThe Z12C type expansion coupling sleeve is suitable for the connection of the shaft and the parts on the shaft to transmit torque, axial force... LXS star elastic couplingThe standard of Ever-PowerLXS star elastic coupling is JB/T 10466-2004, XLS series double flange type star elastic...

LXS star elastic couplingThe standard of Ever-PowerLXS star elastic coupling is JB/T 10466-2004, XLS series double flange type star elastic... SWC_WH couplingThe universal coupling is characterized by its large angular compensation capability and tight structure...

SWC_WH couplingThe universal coupling is characterized by its large angular compensation capability and tight structure...Drum shapeGear couplingThe internal structure is very complicated, and the materials used can meet the requirements of torque and speed..The materials used have certain requirements to meet the requirements of torque and speed!Generally, the commonly used materials are42crmoAnd45More steel forgings.These two materials are mainly used by themselves. The higher the hardness of the material, the better, the greater the torque carried, and the longer the life of the coupling!

GICL,GICLZType-drum gear coupling

GⅡCL,GⅡCLZType-drum gear coupling

GCLD Type-drum gear coupling

WGP Type-drum gear coupling with brake disc

WGC Type—vertical installation drum gear coupling

WGZ Type—Drum-shaped gear coupling with brake wheel

WGT Type—Connecting to the middle sleeve drum-shaped gear coupling

WGJ Type-drum gear coupling with intermediate shaft

NGCL Type—Drum-shaped gear coupling with brake wheel

NGCLZ Type—Drum-shaped gear coupling with brake wheel

WG Type—Drum-shaped gear coupling with brake wheel

CL型Drum typeGear coupling(Standard type)

CLZ型Drum typeGear coupling(Standard type)

The main advantages of drum gear couplings are:

1, Gear coupling has small radial size and large load capacity. It is often used for shafting transmission under low speed and heavy load conditions. The dynamically balanced gear coupling can be used for high-speed transmission, such as the shafting transmission of gas turbines. .Since the angular compensation of drum gear couplings is greater than that of straight gear couplings, Lingsi drum gear couplings are widely used.Drum-type gear couplings are rigid-flexible couplings.

2, The external teeth of drum-shaped gear couplings are divided into two types of teeth, straight teeth and drum-shaped teeth. Drum-shaped gear couplings can allow larger angular displacement (compared to straight-tooth couplings), which can improve The contact condition of the teeth improves the torque transmission capacity and prolongs the service life.The contact state along the tooth width when there is angular displacement.

3, Drum gear coupling has radial, axial and angular axis deviation compensation capabilities, has the advantages of compact structure, small gyration radius, large carrying capacity, transmission, low noise and long maintenance cycle.When the drum gear coupling is working, therefore, the gear coupling needs to work in a good and sealed state.

4, After carburizing and quenching treatment of drum-shaped tooth meshing tooth surface, the bearing capacity is high; the main failure mode of drum-shaped tooth is wear. After using forced thin oil lubrication, the tooth surface wear is greatly reduced, and the amount of wear is the percentage of grease lubrication. Of10Around the left and right, the circulating thin oil can take away the rolling heat at the end of the roll and the heat generated by the friction of the gear teeth, preventing the reduction of the allowable contact stress on the surface of the gear tooth material; under normal circumstances, there will be no tooth breakage, which meets the working characteristics of continuous rolling mills. Requirements: The drum-shaped gear coupling can meet the requirements of rolling mill shifting rolling, and it is very convenient to expand and contract.