Z4 type expansion joint sleeveCompared with the Z4 type, the Z2 type expansion coupling sleeve has a long joint surface and high centering accuracy. It is used for rotation accuracy...

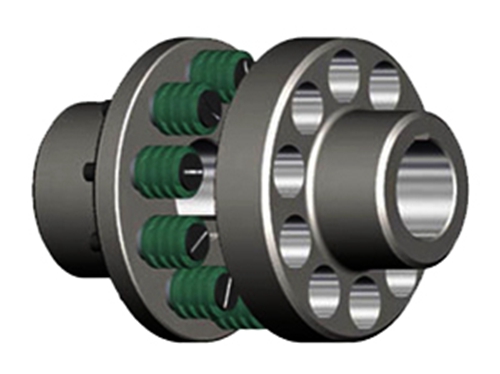

Z4 type expansion joint sleeveCompared with the Z4 type, the Z2 type expansion coupling sleeve has a long joint surface and high centering accuracy. It is used for rotation accuracy... LT elastic sleeve pin couplingLT elastic sleeve pin coupling is a non-metal elastic element flexible coupling, and its structure is similar to the convex...

LT elastic sleeve pin couplingLT elastic sleeve pin coupling is a non-metal elastic element flexible coupling, and its structure is similar to the convex... Elastic sleeve pin coupling for pumpElastic sleeve pin couplings for pumps generally use flexible couplings for the purpose of transmitting power and compensating...

Elastic sleeve pin coupling for pumpElastic sleeve pin couplings for pumps generally use flexible couplings for the purpose of transmitting power and compensating... LLA tire couplingLLA tire couplings are made into non-standard couplings according to special needs. When overloaded,...

LLA tire couplingLLA tire couplings are made into non-standard couplings according to special needs. When overloaded,... GY, GYS, GYH type couplingThe surface roughness of GY, GYS, GYH couplings refers to the small spacing and...

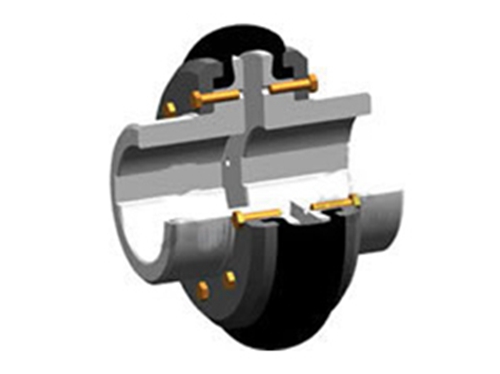

GY, GYS, GYH type couplingThe surface roughness of GY, GYS, GYH couplings refers to the small spacing and...The coupling of the wind turbine is mainly used to transmit power, but it has higher requirements for transmission accuracy.During this period, not only must avoid non-metal elastic elements, but also avoid gaps between movable elements.Under this condition, the high-speed rotation process is prevented, and the coupling is prevented from being damaged.

Because different couplings have different load bearing capacities, the load that the plum-blossom flexible coupling on the wind turbine generator bears is mainly affected by the impeller, gearbox and generator.If the coupling is affected by its own center of mass and inertia, the unbalanced state of centrifugal inertia will also occur during operation.

Rotor misalignment usually refers to the degree of inclination or deviation between the axis centers of two adjacent rotors and the center lines of the bearings.Rotor misalignment can be divided into coupling misalignment and bearing misalignment.

Plum-shaped flexible couplings are in my country, and the capacity of wind turbines ranges from 500KW to 5MW. The mainstream models on the domestic market are 1.5MW. Most of the more than 2MW are under development, and a small number of 4MW and 5MW models are in use. In trial operation.

In the process of using the crane, the user company should require the manufacturer to provide the corresponding qualification certificate. The manufacturer should also provide the electrical schematic diagram, general diagram, main force-bearing component diagram, installation, use and maintenance instructions of the construction crane, etc., and the maintenance of the crane. Maintenance contracts and inspection reports should also be in place.

Wear is a common defect of gear couplings. During operation, due to relative sliding between the inner and outer gear rings of the coupling, this is the basic cause of wear.

For rail-mounted gantry cranes, plum-shaped elastic couplings have common cable drum failures as follows: cable drum loose cable failure, drum mechanical failure, drum electrical circuit failure, and so on.

The quality requirements of the fan manufacturers also affect the operation of the fan, such as: poor parts processing and manufacturing, insufficient precision; poor parts material, insufficient strength, manufacturing defects; rotor dynamic balance does not meet the technical requirements, etc.