NGCL drum gear couplingWhen the NGCL drum gear coupling is working, the two shafts produce relative angular displacement, and the tooth surfaces of the inner and outer teeth...

NGCL drum gear couplingWhen the NGCL drum gear coupling is working, the two shafts produce relative angular displacement, and the tooth surfaces of the inner and outer teeth... LT elastic sleeve pin couplingLT elastic sleeve pin coupling is a non-metal elastic element flexible coupling, and its structure is similar to the convex...

LT elastic sleeve pin couplingLT elastic sleeve pin coupling is a non-metal elastic element flexible coupling, and its structure is similar to the convex... Z7A type locking coupling plateThe Z7 expansion sleeve is a keyless coupling device between the shaft and the sleeve. This device can align the shaft from the outside...

Z7A type locking coupling plateThe Z7 expansion sleeve is a keyless coupling device between the shaft and the sleeve. This device can align the shaft from the outside... SWC_WH couplingThe universal coupling is characterized by its large angular compensation capability and tight structure...

SWC_WH couplingThe universal coupling is characterized by its large angular compensation capability and tight structure... Z19A type expansion joint sleeveZ19A type expansion coupling sleeve is the main product of our company, which has attracted much attention in the industry. Z...

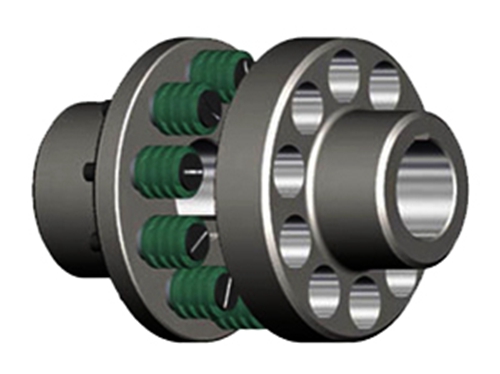

Z19A type expansion joint sleeveZ19A type expansion coupling sleeve is the main product of our company, which has attracted much attention in the industry. Z...The plum blossom coupling is suitable for connecting two coaxial transmission shafts. It has the functions of compensating the relative deviation of the two shafts, buffering, damping, and adapting to general occasions.

Ordinary plum coupling transmission parts work for a long time, the inner hole and chain groove are easy to damage, while the cone sleeve transmission parts can be restored to use only by changing the cone sleeve. Its load-bearing, centering performance, easy installation, long service life and overload protection function Couplings belong to the category of general mechanical parts and are used to connect two shafts (active shaft and driven shaft) in different mechanisms to rotate together to transmit torque.In high-speed and heavy-load power transmission, some couplings also have the function of buffering, damping and improving the dynamic performance of the shafting.

The plum blossom coupling is composed of two halves, which are respectively connected with the driving shaft and the driven shaft.The general power machine is mostly connected with the working machine by means of a coupling, which is a commonly used connection part for the shaft transmission of mechanical products.

The principles that the plum blossom coupling of the torque sensor needs to abide by:

0.2. In general, when the sensor is installed, the selected coupling is a rigid connection, with greater vibration, and when the concentricity is small and 0.05mm is greater than XNUMXmm, elastic connection is recommended.Rigid connection can be used outside this range.

XNUMX. When the torque sensor is in use, it should be installed between the power source and load of the two sets of couplings, and the power load and load equipment should be fixed to avoid vibration, otherwise the instrument will not work normally.

XNUMX. When using a standard torque meter, no matter what method is used for installation, the coupling must bear the axial force and bending moment, try to avoid excessive force on the meter, which will directly cause the meter to be damaged and cannot be used.