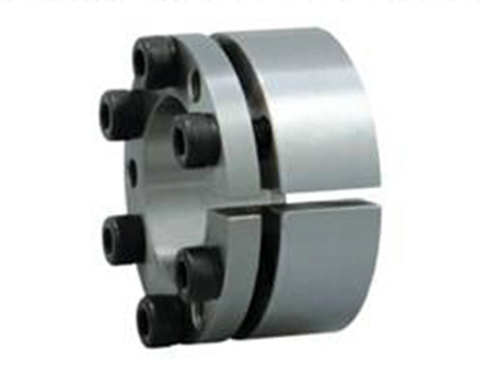

Z7A type locking coupling plate, Is a good choice.Our company's products, complete configuration and thoughtful service have made the products spread all over the world.

The Z7 expansion sleeve is a keyless coupling device between the shaft and the sleeve. This device can apply a clamping force to the sleeve from the outside to form a mechanical compression fit between the shaft and the sleeve, thereby transmitting torque and expanding the sleeve. It does not transmit any torque or load by itself.

When the expansion sleeve is fixed to the proper position of the sleeve (hub), tighten the bolts according to the given torque, and the tapered inner ring exerts radial force on the sleeve. This forced friction coupling can transmit large torque and load.

When the expansion sleeve is clamped, each mating surface has a high pressure and is sealed, which avoids the corrosion of the mating surface.When disassembling, loosen the bolts, the mating surface will automatically relax, and the sleeve and cone ring will automatically return to the original size.

Selection and installation sequence of various locking disks:

When the shaft diameter is the design requirement, select the shrink disk in this product catalog according to the shaft diameter (dw) selected by the design, and check whether the corresponding large transmission torque (Mt) can meet the torque requirement.

On the contrary, if the torque is required, select the required torque (Mt) from the catalog according to the appropriate model, and then find the corresponding shaft diameter (dw).

II. Check the size and strength of the shaft and sleeve according to the selected lock disk.

The outer diameter (d) of the sleeve or hollow shaft is consistent with the inner diameter of the locking disc.The small cross section of the bushing can transmit the specified torque.

The rated torque Mt and rated axial load Pax listed in catalog III are listed in accordance with the maximum value that can be transmitted by the shrink disk without a coefficient. The starting and impact load should be considered when checking.

IV The relationship between the transmission torque value (Mt) and the shaft diameter (dw) is a linear function relationship. All the rated torques corresponding to the shaft diameter are not listed in the model catalog table, but a certain shaft diameter can be obtained by interpolation. The transmitted torque.

for example:

To connect a 103mm shaft, a shrink disk must be installed, and its maximum transmission torque is determined to be 12400Nm. Select the shrink disk model and specifications.

Step: The diameter of the shaft is close to 100mm. ,

步:在标准系列71型规格表中,找出轴径100mm对应锁紧盘型号为SD140-71,用插放法计算出 103mm轴可传递 大扭矩为17600Nm与20100Nm间的19100Nm。

The third step: verify the size of the determined locking disk and design it on the drawing.

Step XNUMX: Find out the required processing tolerances and applicable matching methods.

That is: the tolerance of the shaft and the inner hole of the shaft sleeve is H7/h6, and the outer diameter of the shaft sleeve is f7.

Step 140: Choose the shrink disk, and order according to the following model: the shrink disk SD71-XNUMX.

The basic dimensions of Z7A type locking coupling plate:

| basic size | Socket head cap screws | Rated load | Screw Tighten Torque MA N · m |

weight kg |

|||||||

| d | D | dn | L | H | e | d1 | n | Axial force F1 KN |

Torque M1 KN·m |

||

| mm | |||||||||||

| 125 | 185 | 95 | 39 | 52 | 6 | M10 × 40 | 8 | 242 | 11.5 | 58 | 6 |

| 100 | 260 | 13 | |||||||||

| 105 | 276 | 14.5 | |||||||||

| 140 | 220 | 110 | 10 | 391 | 16 | 8 | |||||

| 120 | 330 | 20 | |||||||||

| 125 | 352 | 22 | |||||||||

| 155 | 245 | 130 | 12 | 385 | 25 | 10 | |||||

| 135 | 427 | 28.8 | |||||||||

| 140 | 464 | 32.5 | |||||||||

| 165 | 260 | 135 | 46 | 62 | 8 | M12 × 50 | 10 | 474 | 32 | 100 | 14 |

| 140 | 507 | 32.5 | |||||||||

| 145 | 538 | 39 | |||||||||

| 175 | 275 | 145 | 538 | 39 | 16 | ||||||

| 150 | 573 | 43 | |||||||||

| 155 | 606 | 47 | |||||||||

| 185 | 295 | 155 | 12 | 632 | 49 | 20 | |||||

| 160 | 662 | 53 | |||||||||

| 165 | 691 | 57 | |||||||||

| 195 | 315 | 165 | 56 | 72 | M12 × 55 | 15 | 800 | 66 | 27 | ||

| 170 | 835 | 71 | |||||||||

| 175 | 869 | 76 | |||||||||

| 220 | 345 | 180 | 66 | 84 | 9 | M16 × 65 | 9 | 978 | 88 | 240 | 35 |

| 190 | 1063 | 101 | |||||||||

| 200 | 1140 | 114 | |||||||||

| 240 | 370 | 200 | 12 | 1200 | 120 | 44 | |||||

| 210 | 1276 | 134 | |||||||||

| 215 | 1312 | 141 | |||||||||

| 260 | 395 | 220 | 72 | 92 | M16 × 70 | 1309 | 144 | 48 | |||

| 230 | 1384 | 159 | |||||||||

| 235 | 1421 | 167 | |||||||||

| 280 | 425 | 230 | 84 | 104 | 10 | M16 × 75 | 15 | 1478 | 170 | 60 | |

| 240 | 1583 | 190 | |||||||||

| 250 | 1680 | 210 | |||||||||

| 300 | 460 | 250 | 16 | 1704 | 213 | 75 | |||||

| 260 | 1800 | 234 | |||||||||

| 270 | 1889 | 255 | |||||||||

| 320 | 495 | 270 | 106 | 11 | M16 × 80 | 18 | 1955 | 264 | 84 | ||

| 280 | 2036 | 285 | |||||||||

| 290 | 2076 | 301 | |||||||||

| 340 | 535 | 290 | 20 | 2193 | 318 | 100 | |||||

| 300 | 2300 | 345 | |||||||||

| 305 | 2354 | 359 | |||||||||

| 360 | 555 | 300 | 100 | 122 | M20 × 90 | 15 | 2547 | 382 | 470 | 125 | |

| 310 | 2645 | 410 | |||||||||

| 320 | 2738 | 438 | |||||||||

| 390 | 595 | 330 | 112 | 136 | 12 | M20 × 100 | 18 | 3091 | 510 | 156 | |

| 340 | 3194 | 543 | |||||||||

| 350 | 3291 | 576 | |||||||||

| 420 | 630 | 350 | 120 | 144 | 20 | 3371 | 590 | 185 | |||

| 360 | 3500 | 630 | |||||||||

| 370 | 3620 | 670 | |||||||||

| 460 | 685 | 390 | 132 | 158 | 13 | M20 × 110 | 24 | 3949 | 770 | 470 | 235 |

| 400 | 4300 | 860 | |||||||||

| 410 | 4634 | 950 | |||||||||

| 500 | 750 | 420 | 152 | 178 | M20 × 120 | 30 | 4881 | 1025 | 320 | ||

| 430 | 5233 | 1125 | |||||||||

| 440 | 5568 | 1225 | |||||||||

Conveyor special coupling

Conveyor couplings are used to connect different machines...

Conveyor special coupling

Conveyor couplings are used to connect different machines...

Z17A type expansion joint sleeve

The Z17A type expansion joint sleeve consists of an open...

Z17A type expansion joint sleeve

The Z17A type expansion joint sleeve consists of an open...

Z3 type expansion coupling sleeve

Z3 type expansion joint sleeve characteristics: Z3 type expansion...

Z3 type expansion coupling sleeve

Z3 type expansion joint sleeve characteristics: Z3 type expansion...

SWP_A universal coupling

SWP_A universal coupling has a large angle compensation...

SWP_A universal coupling

SWP_A universal coupling has a large angle compensation...