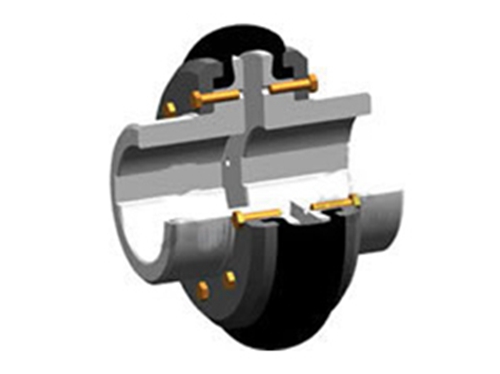

NGCL drum gear couplingIt is composed of internal gear ring with the same number of teeth and flange half coupling with external teeth.The external teeth are divided into straight teeth and drum teeth. The so-called drum teeth means that the external teeth are made into a spherical surface. The spherical surface is on the gear axis. The tooth side clearance is larger than that of ordinary gears. Drum-shaped gear couplings allow Larger angular displacement (compared to spur gear coupling), the contact condition of the teeth can be improved, the ability of transmitting torque is improved, and the service life is prolonged.

NGCL drumGear couplingWhen working, the two shafts produce relative angular displacement, and the tooth surfaces of the internal and external teeth periodically slide relative to each other in the axial direction, which will inevitably cause tooth surface wear and power consumption. Therefore, the gear coupling needs to work in a good and sealed state. .Gear couplings have small radial dimensions and large load-bearing capacity. They are often used in shaft transmissions under low-speed and heavy-duty conditions. The dynamically balanced gear couplings can be used for high-speed transmissions, such as gas turbine shaft transmissions.

| model | Nominal torque Tn (KN.m) | Allowable speed n (r/min) | Diameter of shaft hole | Shaft hole length L | D0 | D | D1 | D2 | B3 | Weight Kg | ||

| dz | d1 d2 | Y | J1 Z1 | |||||||||

| NGCL1 | 355 | 4000 | 20 ~ 35 | 20 22 24 | 52 | 38 | 160 | 103 | 71 | 50 | 68 | 7 |

| 25 28 | 62 | 44 | 7.3 | |||||||||

| 30 32 35 | 82 | 60 | 8 | |||||||||

| NGCL2 | 630 | 4000 | 25 ~ 45 | 25 28 | 62 | 44 | 160 | 115 | 83 | 60 | 68 | 9 |

| 30 32 35 38 | 82 | 60 | 9.7 | |||||||||

| 40 42 45 | 112 | 84 | 11 | |||||||||

| NGCL3 | 1000 | 3800 | 30 ~ 55 | 28 | 62 | 44 | 200 | 127 | 95 | 75 | 85 | 14.6 |

| 30 32 35 38 | 82 | 60 | 15.2 | |||||||||

| 40 42 45 48 50 55 56 | 112 | 84 | 17 | |||||||||

| NGCL4 | 1600 | 3800 | 40 ~ 65 | 38 | 82 | 60 | 200 | 149 | 116 | 90 | 85 | 18.6 |

| 40 42 45 48 50 55 56 | 112 | 84 | 21.4 | |||||||||

| 60 63 65 | 142 | 107 | 23.8 | |||||||||

| NGCL5 | 2800 | 3000 | 45 ~ 75 | 40 42 45 48 50 55 56 | 112 | 84 | 250 | 167 | 134 | 105 | 105 | 31.8 |

| 60 63 65 70 71 75 | 142 | 107 | 34.4 | |||||||||

| NGCL6 | 4500 | 3000 | 50 ~ 90 | 45-48 | 112 | 84 | 250 | 187 | 153 | 125 | 105 | 37.2 |

| 60 63 65 70 71 75 | 142 | 107 | 38.5 | |||||||||

| 80 85 90 | 172 | 132 | 47.6 | |||||||||

| NGCL7 | 6300 | 2400 | 60 ~ 100 | 50 55 56 | 112 | 84 | 315 (300) | 204 | 170 | 140 | 132 | 48.8 |

| 60 63 65 70 71 75 | 142 | 107 | 55.2 | |||||||||

| 80 85 90 95 | 172 | 132 | 61.8 | |||||||||

| 100 | 212 | 167 | 71.1 | |||||||||

| NGCL8 | 9000 | 1900 | 70 ~ 110 | 55 56 | 112 | 84 | 400 | 230 | 186 | 155 | 168 | 80.7 |

| 60 63 65 70 71 75 | 142 | 107 | 90 | |||||||||

| 80 85 90 95 | 172 | 132 | 96.5 | |||||||||

| 100 110 | 212 | 167 | 108 | |||||||||

| NGCL9 | 14000 | 1500 | 80 ~ 130 | 60 63 65 70 71 75 | 142 | 107 | 500 | 256 | 212 | 180 | 210 | 128 |

| 80 85 90 95 | 172 | 132 | 138 | |||||||||

| 100 110 120 125 | 212 | 167 | 151 | |||||||||

| 130 | 252 | 202 | 167 | |||||||||

| NGCL10 | 20000 | 1200 | 80 ~ 150 | 65 70 71 75 | 142 | 107 | 630 (600) | 287 | 239 | 200 | 265 | 176 |

| 80 85 90 95 | 172 | 132 | 190 | |||||||||

| 100 110 120 125 | 212 | 167 | 209 | |||||||||

| 130 140 150 | 252 | 202 | 237 | |||||||||

| NGCL11 | 31500 | 1050 | 100 ~ 170 | 70 71 75 | 142 | 107 | 710 (700) | 325 | 276 | 235 | 298 | 257 |

| 80 85 90 95 | 172 | 132 | 275 | |||||||||

| 100 110 120 125 | 212 | 167 | 300 | |||||||||

| 130 140 150 | 252 | 202 | 326 | |||||||||

| 160 170 | 302 | 242 | 357 | |||||||||

| NGCL12 | 45000 | 1050 | 100 ~ 200 | 75 | 142 | 107 | 710 (700) | 362 | 313 | 270 | 298 | 306 |

| 80 85 90 95 | 172 | 132 | 317 | |||||||||

| 100 110 120 125 | 212 | 167 | 351 | |||||||||

| 130 140 150 | 252 | 202 | 384 | |||||||||

| 160 170 180 | 302 | 242 | 425 | |||||||||

| 190 200 | 352 | 282 | 464 | |||||||||

| NGCL13 | 63000 | 950 | 150 ~ 220 | 150 | 252 | 202 | 800 | 412 | 350 | 300 | 335 | 490 |

| 160 170 180 | 302 | 242 | 544 | |||||||||

| 190 200 220 | 352 | 282 | 596 | |||||||||

| NGCL14 | 100000 | 950 | 170 ~ 220 | 170 180 | 302 | 242 | 800 | 462 | 420 | 335 | 335 | 670 |

| 190 200 220 | 352 | 282 | 736 | |||||||||

| 240 250 | 410 | 330 | 785 | |||||||||

LLA tire coupling

LLA tire coupling is made as required...

LLA tire coupling

LLA tire coupling is made as required...

JS serpentine spring coupling

The JS serpentine spring coupling has good damping performance, so...

JS serpentine spring coupling

The JS serpentine spring coupling has good damping performance, so...

Z20 type expansion joint sleeve

The Z20 type expansion joint sleeve has a good mutual...

Z20 type expansion joint sleeve

The Z20 type expansion joint sleeve has a good mutual...

NGCL drum gear coupling

When the NGCL drum gear coupling is working,...

NGCL drum gear coupling

When the NGCL drum gear coupling is working,...