WGP drum gear couplingWGP drum gear coupling can allow larger angular displacement (relative to straight gear coupling), which can...

WGP drum gear couplingWGP drum gear coupling can allow larger angular displacement (relative to straight gear coupling), which can... Special-shaped coupling modification productsThe special-shaped coupling modification products are characterized by simple structure, easy installation, changeover...

Special-shaped coupling modification productsThe special-shaped coupling modification products are characterized by simple structure, easy installation, changeover... Polyurethane plum-shaped elastomerPolyurethane plum-shaped elastomer is a plum-shaped elastic element made of polyurethane material, which...

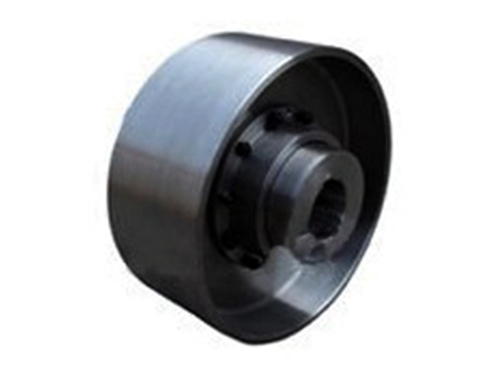

Polyurethane plum-shaped elastomerPolyurethane plum-shaped elastomer is a plum-shaped elastic element made of polyurethane material, which... Brake wheelThe quality and sales of the brake wheels produced by our company are in the same industry...

Brake wheelThe quality and sales of the brake wheels produced by our company are in the same industry... KC series sprocket couplingThe KC series sprocket coupling uses a common chain to connect two sprocket teeth with the same number of teeth...

KC series sprocket couplingThe KC series sprocket coupling uses a common chain to connect two sprocket teeth with the same number of teeth...XNUMX. Slider coupling

The slider coupling is also known as the metal slider coupling. Its slider is ring-shaped and made of steel or alloy. It is suitable for transmissions with low speed and large transmission torque. The slider coupling and the cross The structure of the slider coupling is similar. The difference is that the middle cross slider is a square slider. The middle slider is used to slide in the corresponding radial grooves on the end faces of the half couplings on both sides to realize the coupling of the two halves. .

Cross slider couplings are noisy, low in efficiency, and wear quickly. Generally, they should not be used as much as possible. They should only be used when the speed is very low, such as ball mills.

XNUMX. Clamping coupling

The clamp shell coupling uses two clamp shells split along the axial direction, which are clamped by bolts to realize the connection of the two shafts. The torque is transmitted by the friction between the two halves of the coupling surface, and the flat key is used as an auxiliary connection.

The housing coupling does not need to move axially when assembling and disassembling, so the assembly and disassembly is very convenient. The disadvantage of the housing coupling is the low accuracy of the axis of the two shafts, the structure and shape are more complicated, and the manufacturing and balance accuracy is low , It is only suitable for the occasions of low speed and stable load. Usually the speed of the outer edge is not more than 5m/s. When the linear speed exceeds 5m/s, a balance check is required.In order to balance the situation, the bolts should be installed between the forward and reverse phases.Jacketed couplings do not have axial, radial and angular compensation performance.The characteristics of the vertical jacket coupling are similar to those of the jacket coupling, simple structure, convenient assembly and disassembly, suitable for low-speed, no impact, and stable vibration loads. It is suitable for the connection of vertical shafts such as agitators.

Three, flange coupling

Flange coupling is a rigid coupling. It connects two flanged half couplings to the two shafts with ordinary flat keys, and then connects the two half couplings into one body with bolts to transmit Movement and torque.This kind of coupling has two main structural forms: ①The reaming hole uses bolts to realize the centering of the two shafts and the bolt rod to withstand extrusion and shear to transmit torque; ②Rely on a half coupling The shoulder is aligned with the groove on the other half coupling to be centered.The bolts connecting the two half couplings can be used with ordinary bolts of grade B, and the torque is transmitted by the frictional moment of the joint surface of the two half couplings.

The material of the flange coupling can be gray cast iron or carbon steel, and cast steel or forged steel should be used under heavy load or when the peripheral speed is greater than 30 m/s.Flange couplings have high requirements for the neutrality of the two shafts. When the two shafts have relative displacement, they will cause additional loads in the machine parts and worsen the working conditions. This is its main disadvantage.However, due to the simple structure, low cost, and large torque transmission, it is often used when the speed is low, there is no impact, the shaft is rigid, and the neutrality is good.