HLL type-elastic pin couplingHLL type-elastic pin coupling is a pin made of a number of non-metal elastic materials, placed in...

HLL type-elastic pin couplingHLL type-elastic pin coupling is a pin made of a number of non-metal elastic materials, placed in... SL cross slider couplingThe SL cross slider coupling is also known as the metal slider coupling. There are two end faces with radial grooves...

SL cross slider couplingThe SL cross slider coupling is also known as the metal slider coupling. There are two end faces with radial grooves... JSJ type serpentine spring couplingDue to manufacturing and installation errors, the two shafts connected by the JSJ serpentine spring coupling will change...

JSJ type serpentine spring couplingDue to manufacturing and installation errors, the two shafts connected by the JSJ serpentine spring coupling will change... Keyway flange diaphragm couplingThe keyway flange diaphragm coupling relies on the elastic deformation of the diaphragm to compensate the relative displacement of the connected two shafts,...

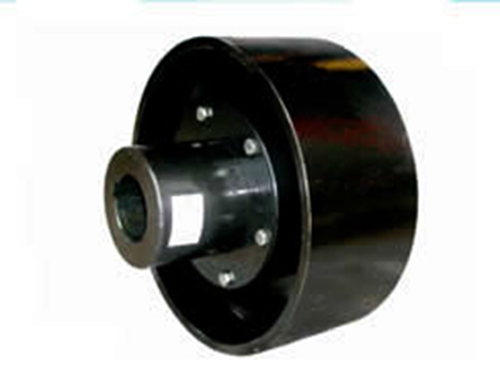

Keyway flange diaphragm couplingThe keyway flange diaphragm coupling relies on the elastic deformation of the diaphragm to compensate the relative displacement of the connected two shafts,... Nylon sleeve inner gear ringNylon inner gear ring is a group of parts such as a flange half coupling with external teeth and an inner gear ring with the same number of teeth...

Nylon sleeve inner gear ringNylon inner gear ring is a group of parts such as a flange half coupling with external teeth and an inner gear ring with the same number of teeth...The elastic coupling is cut by a metal round bar wire, and the commonly used materials are generally aluminum alloy, stainless steel and engineering plastics.The elastic coupling uses two grooving systems, parallel or spiral, to adjust to accommodate deviations and transmit torque.In the practical application of many step systems, elastic couplings are generally the products of.The one-piece design enables the elastic coupling to realize the advantages of zero-clearance torque transmission and no maintenance.

Flexible couplings are suitable for light load applications.For example, the connection of a servo motor and a ball screw.However, this kind of performance will increase the bearing load as the slot size increases, but in most cases, it can adequately protect the bearing.Increasing size means increasing the ability to withstand eccentricity.

The elastic coupling uses parallel or spiral groove system to adapt to various deviations and transmit torque.Flexible couplings usually have good performance and price advantages. In many practical applications of stepping and servo systems, flexible couplings are the most popular products.The one-piece design enables the flexible coupling to achieve the advantages of zero-clearance torque transmission and no maintenance.The elastic coupling mainly has the following two basic series: spiral groove type and parallel groove type.

Performance advantages of flexible couplings:

1. One-piece metal elastomer.

2. Zero backlash, synchronous operation.

3. The elastic action compensates radial, angular and axial deviations.

4. High torque rigidity and high sensitivity.

5. The characteristics of clockwise and counterclockwise rotation are the same.

6. Maintenance-free, oil-resistant and sexual.

7. There are aluminum alloy and stainless steel materials to choose from.

8. There are two main fixing methods: top wire and clamping.Try to avoid excessive load on the meter, which will directly cause the meter to be damaged and unusable.