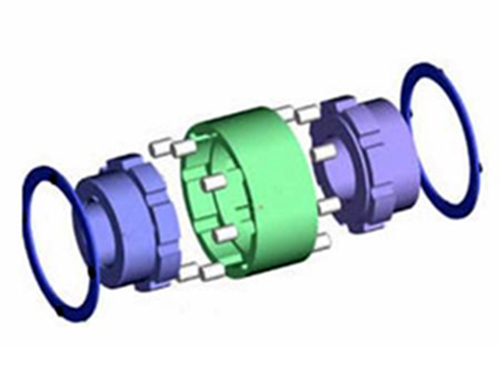

Nylon sleeve inner gear ringIt is composed of a flange half coupling with external teeth and an internal gear ring with the same number of teeth.The external teeth are divided into two types: drum teeth and straight teeth. The so-called drum-shaped nylon inner gear ring means that the external teeth are made into a spherical surface. The spherical surface is on the gear axis. The tooth side clearance is larger than that of ordinary gears. The inner gear coupling can allow a larger angular displacement (compared to the straight tooth coupling), and the contact conditions of the teeth can be improved to improve the torque transmission capacity and extend the service life.

Uses of Nylon Sleeve Gear Ring:

Forging, construction, mining, plastics, food, engineering, petroleum, chemical, machine tools, ships, leather, textiles, fans, pumps and other industries machinery transmission.The internal tooth elastic coupling uses better couplings with other structures.

LXP star coupling

LXP star coupling is made of engineering plastic...

LXP star coupling

LXP star coupling is made of engineering plastic...

GICLZ drum gear coupling

GICLZ drum gear coupling drum tooth surface...

GICLZ drum gear coupling

GICLZ drum gear coupling drum tooth surface...

ZLD type elastic pin gear coupling

ZLD type elastic pin gear coupling is advantageous...

ZLD type elastic pin gear coupling

ZLD type elastic pin gear coupling is advantageous...

ML plum blossom coupling

The ML plum blossom coupling has a simple structure and...

ML plum blossom coupling

The ML plum blossom coupling has a simple structure and...