SWCCH couplingSWCCH coupling is a commonly used coupling.Using the characteristics of its structure can make...

SWCCH couplingSWCCH coupling is a commonly used coupling.Using the characteristics of its structure can make... CL type gear couplingCL type gear coupling is a removable rigid coupling, consisting of two housings with internal teeth and two...

CL type gear couplingCL type gear coupling is a removable rigid coupling, consisting of two housings with internal teeth and two... LXJ star elastic couplingThe standard of LXJ star elastic coupling is JB/T 10466-2004.Star couplings are sometimes mistaken for...

LXJ star elastic couplingThe standard of LXJ star elastic coupling is JB/T 10466-2004.Star couplings are sometimes mistaken for... JMI diaphragm couplingThe JMI diaphragm coupling belongs to the JM series of diaphragm couplings that can compensate the driving machine and the driven machine...

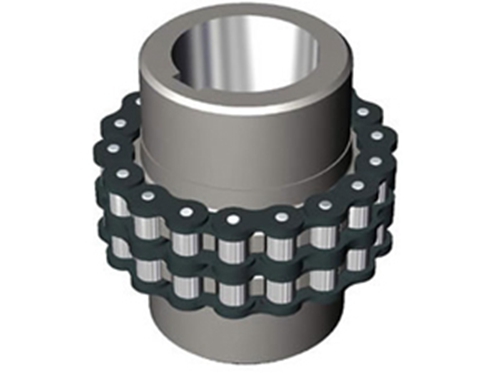

JMI diaphragm couplingThe JMI diaphragm coupling belongs to the JM series of diaphragm couplings that can compensate the driving machine and the driven machine... GL type roller chain couplingThe GL type roller chain coupling has a simple structure (composed of four pieces), convenient assembly and disassembly, and does not...

GL type roller chain couplingThe GL type roller chain coupling has a simple structure (composed of four pieces), convenient assembly and disassembly, and does not...There are two main types of plum blossom couplings, one is the traditional straight claw type, and the other is the curved (concave) claw type zero-backlash coupling.The traditional straight-jaw plum blossom coupling is not suitable for use in high-precision servo transmission applications.The zero-backlash claw type plum blossom coupling is evolved on the basis of the straight claw type, but the difference is that its design can be suitable for the application of the servo system, and is often used to connect servo motors, stepping motors and ball screws.The curved surface is to reduce the deformation of the elastic plum spacer and limit the influence of centripetal force on it during high-speed operation.The zero-clearance claw coupling is composed of two metal sleeves (usually made of aluminum alloy, stainless steel can also be provided) and a plum blossom elastic spacer.The plum blossom elastic spacer has multiple leaf branches. Like a slider coupling, it also squeezes the plum blossom elastic spacer and the sleeves on both sides to match, and thus its zero clearance performance.Different from the slider coupling, the plum blossom coupling is driven by squeezing while the slider coupling is driven by shear.When using a zero-clearance claw coupling, the user should pay attention not to exceed the large bearing capacity of the elastic element given by the manufacturer (under the premise of zero clearance), otherwise the plum elastic spacer will be squashed and deformed and lose its elasticity. The disappearance of the preload, resulting in the loss of zero-gap performance, may also be discovered by the user after a serious problem occurs.

The plum coupling has a good balance performance and is suitable for high-speed applications (high speed up to 30000 rpm), but it cannot handle large deviations, especially axial deviations.Larger eccentricity and deflection angle will produce a larger bearing load than other servo couplings.Another issue of concern is the failure of the plum blossom coupling.Once the quincunx elastic spacer is damaged or fails, the torque transmission will not be interrupted, and the metal claws of the two shaft sleeves mesh together to continue to transmit the torque, which is likely to cause problems in the system.Choosing the appropriate plum blossom elastic spacer material according to the actual application is a major advantage of this coupling. Some automation equipment companies can provide plum blossom spacers of various elastic materials, with different hardness and temperature resistance, so that customers can choose the right material. Meet the performance standards of practical applications.

The assembly of the coupling is a relatively simple maintenance process in mechanical maintenance.The key to the assembly of the coupling is to master the assembly of the hub on the shaft, the alignment of the two shafts connected by the coupling, the inspection of parts and components, and the assembly of the coupling according to the requirements of the drawings.

The plum blossom coupling is a widely used coupling, also called a claw coupling, which is composed of two metal claw discs and an elastic body.The two metal claws are generally made of No. 45 steel, but aluminum alloys are also useful when load sensitivity is required.

The plum blossom coupling is processed by machining methods such as turning, milling, and broaching, and then undergoes overall heat treatment.With sufficient mechanical strength, there is also a kind of claw plate on the market that is a casting, which can be produced in large quantities and eliminates processing losses.So the price is much lower than machining.But the performance of the casting is not very good.It is better not to use it in some important occasions.In addition, the claws of the casting are prone to snapping under high speed or high load conditions.