LM (ML) plum blossom couplingThe LM (ML) plum coupling is mainly composed of two protruding teeth closely meshed and subjected to radial compression to transmit torsion...

LM (ML) plum blossom couplingThe LM (ML) plum coupling is mainly composed of two protruding teeth closely meshed and subjected to radial compression to transmit torsion... SWP_D universal couplingThe two shafts connected by the SWP_D universal coupling are deformed after loading due to manufacturing and installation errors...

SWP_D universal couplingThe two shafts connected by the SWP_D universal coupling are deformed after loading due to manufacturing and installation errors... LLA tire couplingLLA tire couplings are made into non-standard couplings according to special needs. When overloaded,...

LLA tire couplingLLA tire couplings are made into non-standard couplings according to special needs. When overloaded,... Nylon sleeve inner gear ringNylon inner gear ring is a group of parts such as a flange half coupling with external teeth and an inner gear ring with the same number of teeth...

Nylon sleeve inner gear ringNylon inner gear ring is a group of parts such as a flange half coupling with external teeth and an inner gear ring with the same number of teeth... JMIJ diaphragm couplingThe JMIJ diaphragm coupling has a strong ability to compensate for the misalignment of the two axes. Compared with the gear coupling, the angular position...

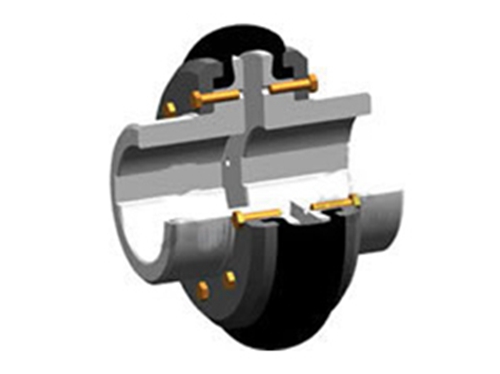

JMIJ diaphragm couplingThe JMIJ diaphragm coupling has a strong ability to compensate for the misalignment of the two axes. Compared with the gear coupling, the angular position...The plum blossom coupling is a widely used coupling, also called a claw coupling, which is composed of two metal claw discs and an elastic body.The two metal claws are generally made of No. 45 steel, but aluminum alloys are also useful when load sensitivity is required.

Plum coupling is a kind of flexible coupling. It is widely used in the transmission field of pulverized coal machine. It is widely favored by customers, such as large dosage, simple use and low price.The working principle of the plum blossom coupling is to install a whole plum blossom-shaped elastic ring on two semi-couplings with the same shape.

The plum coupling is processed by machining methods such as turning, milling, and broaching, and then undergoes overall heat treatment.In order to ensure sufficient mechanical strength, there is also a claw plate on the market that is a casting, which can be produced in large quantities and eliminates processing losses.

There are two main types of plum blossom couplings, one is the traditional straight claw type, and the other is the curved (concave) claw type zero-backlash coupling.The traditional straight-jaw type plum blossom coupling is not suitable for high-precision servo transmission applications.

It is difficult to disassemble various couplings if they are used for a long time. Generally, the connecting bolts should be removed first when disassembling the plum blossom elastic coupling.

The quincunx-shaped elastic coupling is composed of two half-couplings with the same shape of the claws and elastic elements. The quincunx-shaped elastic element is placed between the claws of the two coupling halves to realize the coupling of the two halves. Connection and transmission.

The plum blossom elastic coupling has a high sales volume in the market and is a new product that has attracted attention.Our company has rich experience in couplings, with the conditions and strong advantages of high-tech products and mass production, which can meet the various needs of users.

Ever-Power clamping spline plum blossom type elastic coupling adopts polyurethane plastic as the elastic connecting element, which has good cushioning, shock absorption, performance, one-time molding, and convenient assembly and disassembly.