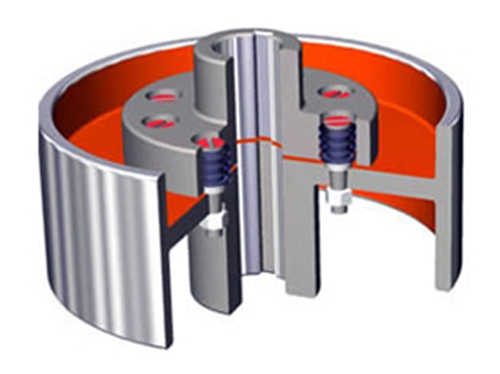

JMIJ diaphragm couplingIt is composed of several groups of diaphragms (stainless steel thin plate) which are connected with two halves of the coupling in a staggered manner with bolts. Each group of diaphragms is composed of several stacked ones. The diaphragms are divided into connecting rod type and whole piece type of different shapes.

The JMIJ diaphragm coupling compensates for the misalignment of the two axes. Compared with the gear coupling, the angular displacement can be doubled, the reaction force is small during radial displacement, the flexibility is large, and some axial, radial and angular displacement are allowed. To displacement. The JMIJ diaphragm coupling is different from the ordinary diaphragm coupling. It is not only connected with an intermediate shaft to extend the transmission distance, but also equipped with two diaphragms to increase the amount of flexibility compensation, so it is also called a double diaphragm coupling.

JMIJDiaphragm couplingIt can accurately transmit the speed without slip, and can be used for mechanical transmission.The transmission reaches 99.86% in the transmission, which is especially suitable for medium, high-speed and high-power transmission.Simple structure, light weight, small size, convenient assembly and disassembly.It can be assembled and disassembled without moving the machine, and no lubrication is required.It is suitable for working in high temperature (-80+300) and harsh environment, and can move under shock and vibration conditions.It has obvious shock absorption, no noise and no wear.

Compared with gear couplings, JMIJ diaphragm couplings have no relative sliding, no lubrication, sealing, noise, basically no maintenance, more convenient manufacturing, and can partially replace gear couplings.Diaphragm couplings have been widely used in the industrially developed industry. In practical applications, the intermediate shaft type is generally used to improve the performance of two-axis offset compensation.

JMIJ diaphragmCouplingIt is suitable for shafting transmission in high temperature, high speed, and corrosive medium conditions. It is widely used for shafting transmission of various mechanical devices, such as water pumps (especially high-power, chemical pumps), fans, compressors, hydraulic machinery, petroleum High-speed power transmission systems of machinery, printing machinery, textile machinery, chemical machinery, mining machinery, metallurgical machinery, aviation (helicopters), and naval vessels are commonly used in high-speed drive shaft systems after dynamic balance.

LMZ quincunx elastic coupling

LMZ quincunx elastic coupling has compensation...

LMZ quincunx elastic coupling

LMZ quincunx elastic coupling has compensation...

ZL type coupling

ZL type coupling is used to connect different machines...

ZL type coupling

ZL type coupling is used to connect different machines...

Z11 type expansion joint sleeve

The comparison between Z11 type expansion coupling sleeve and Z2 type,...

Z11 type expansion joint sleeve

The comparison between Z11 type expansion coupling sleeve and Z2 type,...

LTZ elastic sleeve pin coupling

LTZ elastic sleeve pin coupling structure comparison...

LTZ elastic sleeve pin coupling

LTZ elastic sleeve pin coupling structure comparison...