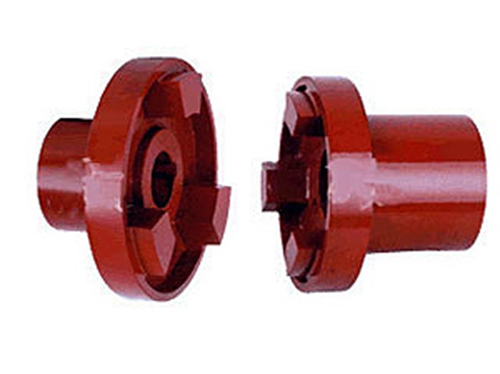

Three-jaw coupling for pumpThe three-jaw coupling for pumps is a kind of water pump coupling, the middle sliding block is made of bakelite or polyurethane...

Three-jaw coupling for pumpThe three-jaw coupling for pumps is a kind of water pump coupling, the middle sliding block is made of bakelite or polyurethane... Z7B type expansion joint sleeveWhen the Z7B expansion coupling sleeve is fixed to the proper position of the shaft sleeve (hub), tighten it according to the given torque...

Z7B type expansion joint sleeveWhen the Z7B expansion coupling sleeve is fixed to the proper position of the shaft sleeve (hub), tighten it according to the given torque... Z7C type expansion joint sleeveThe Z7C type expansion coupling sleeve is a keyless coupling device between the shaft and the sleeve. This device can be...

Z7C type expansion joint sleeveThe Z7C type expansion coupling sleeve is a keyless coupling device between the shaft and the sleeve. This device can be... Gear coupling GIICL typeThe gear coupling GIICL type is composed of an internal gear ring with the same number of teeth and a flange half coupling with external teeth, etc...

Gear coupling GIICL typeThe gear coupling GIICL type is composed of an internal gear ring with the same number of teeth and a flange half coupling with external teeth, etc... High-speed diaphragm couplingThe high-speed diaphragm coupling consists of several sets of diaphragms (stainless steel thin plates) interlaced with two halves with bolts...

High-speed diaphragm couplingThe high-speed diaphragm coupling consists of several sets of diaphragms (stainless steel thin plates) interlaced with two halves with bolts...The elastic coupling is a new type of high-performance coupling developed by our country. It combines the advantages of the existing standard elastic couplings with different structures, such as the advantages of the plum elastic coupling: the elastic element is compressed, the structure is simple, and the performance is high. .Overcome the shortcomings of the quincunx-shaped elastic coupling: When changing the elastic element, move the half coupling, the double-flange quincunx-shaped elastic coupling and the moment of inertia, the application range is limited.When transmitting the same torque, the radial dimension is much smaller than that of GB4323 elastic sleeve pin coupling, with light weight and small moment of inertia.

Performance and requirements of elastic coupling:

1. In order to facilitate a complete understanding of the elastic coupling shaft transmission system, the user should provide the following technical data during use: description and diagrams of the machine and equipment, driving machinery, driven machinery, and auxiliary machinery; the transmission ratio of the system: The moment of inertia of the rotating parts, the inertia of the entire system-elastic data, all size limits; the size of the loading and unloading space, the working state of the connected shaft, balance requirements; the nominal axial distance between the shaft and the shaft or between the flange and the flange , Provide as much as possible the detailed dimensions and tolerances of the connected shaft or flange, the large cantilever load on each shaft; the distance from the proximal bearing of the coupling and the type of bearing, the large axial load of the main and driven shafts.

2. The power of the transmitted speed, including the speed and nominal torque when the speed-torque curve is in normal operation; the allowable large speed and large torque; for the vibration torque expressed in excitement, the instantaneous or continuous frequency should be specified in detail Variation range, instantaneous load during acceleration or deceleration.Nature of work: working conditions (continuous, intermittent, oscillation, forward and reverse, etc.) required life and allowable maintenance time.Environmental data for transportation, storage and use: shock and vibration, ambient temperature and humidity range, the presence of oils, solvents, corrosive liquids, steam, sand, dust, salt water and radiation.The expected deviation between the connected shafts: the general and large deviations allowed in the running state in the angular, radial, and axial directions, and the general and large deviations allowed during operation and parking.The effect of temperature changes.The performance requirements of the Otis coupling: torsional stiffness; axial stiffness, the critical speed of the intermediate shaft coupling.