UL tire couplingUL tire coupling uses tire-like rubber components to connect the two halves of the coupling with bolts. ...

UL tire couplingUL tire coupling uses tire-like rubber components to connect the two halves of the coupling with bolts. ... NGCLZ drum gear couplingThe NGCLZ drum gear coupling consists of an internal gear ring with the same number of teeth and a flange half coupling with external teeth...

NGCLZ drum gear couplingThe NGCLZ drum gear coupling consists of an internal gear ring with the same number of teeth and a flange half coupling with external teeth... LT elastic sleeve pin couplingLT elastic sleeve pin coupling is a non-metal elastic element flexible coupling, and its structure is similar to the convex...

LT elastic sleeve pin couplingLT elastic sleeve pin coupling is a non-metal elastic element flexible coupling, and its structure is similar to the convex... WGZ type gear couplingEver-PowerWGZ type gear coupling structure, flexible operating mechanism, is worth choosing.My company has finished...

WGZ type gear couplingEver-PowerWGZ type gear coupling structure, flexible operating mechanism, is worth choosing.My company has finished... JQ type-jacket couplingThe JQ type-clamping shell coupling uses two axially split clamping shells, which are clamped by bolts to realize two...

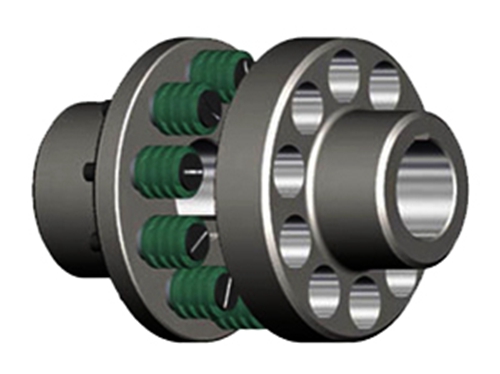

JQ type-jacket couplingThe JQ type-clamping shell coupling uses two axially split clamping shells, which are clamped by bolts to realize two...The plum blossom coupling uses a drum-shaped plum blossom-shaped elastic body to be placed between the two half-coupling claws to realize the elastic connection of the two half-couplings.When the coupling is working, the drum-shaped elastic petals embedded between the driving and driven pawls in the direction of rotation can fully contact the paws of the half-coupling, which compensates for the deviation of the elastomer petal pitch and the convexity of the half-coupling. The claw distance error of the claws makes the elastic body and the coupling uniformly stressed, which improves the load-bearing capacity of the coupling. At the same time, since the cross section of the elastic flap is drum-shaped, the angular displacement compensation of the coupled shaft is greatly improved.

For the vertical joint surface of plum coupling parts, the tolerance level for the round runout of the rotating end face is level 6, and the tolerance level for the round runout of other end faces is level 7; the radial runout tolerance level of the mating surface and the guide surface is level 6 ; The radial runout tolerance level of other cylindrical surfaces is level 7; the coaxiality tolerance level of the rotation of the mating surface and the guide surface is level 5.

The design of the plum blossom coupling considers the axial displacement between the two to be connected, and its value should be greater than 6mm.When the coupling is installed, a compensation amount should be reserved in the direction of thermal expansion.The structure of the gear coupling without spacer sleeve should allow the gear sleeve to make an appropriate amount of axial movement, so that the inner and outer teeth can be separated from the cohesion, so that the working condition of the gear teeth and the equipment need not be disassembled during maintenance.The structure of the coupling should be centered on all parts.The mating inner and outer teeth should be centered by the tooth top.In order to reduce potential imbalances, tooth circumferential backlash.

There are many types, types, and specifications of couplings. On the basis of correct understanding of the respective concepts of types, types and specifications, the coupling should be selected according to the needs of the transmission system. First, choose from the couplings that have been formulated as standards. At present, China There are more than a dozen types of standard couplings formulated as national standards and industry standards. Most of these standard couplings are universal couplings. Each coupling has its own characteristics and scope of application, and can basically meet the needs of various working conditions. Under normal circumstances, designers do not need to design the coupling by themselves, and only need to design the coupling by themselves when the existing standard coupling cannot meet the needs.The standard plum coupling is easy to purchase, and the price is much cheaper than the self-designed non-standard coupling.Among the many standard couplings, the correct choice of the best coupling that suits your needs is related to the working performance, performance, service life, vibration, noise, energy saving, transmission efficiency, transmission accuracy, and economy of the mechanical product shafting transmission. A series of problems are also related to the quality of mechanical products.

The characteristics of plum coupling:

1. The plum blossom coupling is compact, without backlash, and provides three different hardness elastomers.

2. The plum blossom coupling can absorb vibration and compensate for radial and angular deviations.

3. The plum blossom coupling has simple structure, convenient maintenance and easy inspection.

4. Plum blossom coupling is maintenance-free, oil-resistant and electrically insulated, and its working temperature is 20℃-60℃.

5. The elastic body of the plum blossom coupling has four petals, six petals, eight petals and ten petals.

6. The fixing methods of plum blossom coupling include top wire, clamping and keyway fixing.