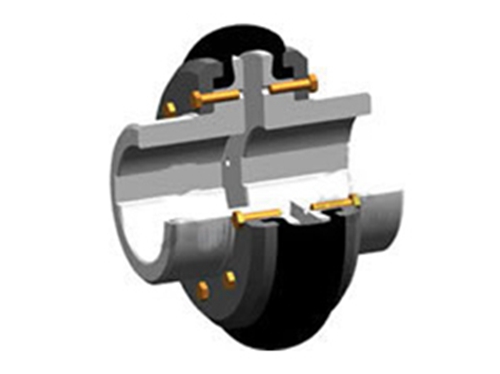

UL tire couplingIt uses tire-like rubber components to connect the two halves of the coupling with bolts.The structure of tire coupling is divided into three types: framed type, open type and integral type.

Compared with the other two types, the framed structure has the advantages of large carrying capacity, long service life, and convenient assembly and disassembly. Therefore, the framed tire coupling is selected as the standard.The tire coupling has high elasticity, low torsional rigidity, vibration reduction, and large ability to compensate for the relative displacement of the two shafts, good damping, simple structure, no lubrication, easy assembly and disassembly and maintenance, low noise, but load-bearing The capacity is not high, the radial dimension is large, and a large axial additional load is generated when overloaded.It is suitable for the two-axis connection with frequent starting, changeable forward and reverse rotation, and large shock and vibration. It can work under dust and moisture conditions. The working temperature is -20~80℃.Specific models: UL1, UL2, UL3, UL4, UL5, UL6, UL7, UL8, UL9, UL10, UL11, UL12, UL13, UL14, UL15, UL16, UL17, UL18.

JSP type serpentine spring coupling

Features of JSP serpentine spring coupling:...

JSP type serpentine spring coupling

Features of JSP serpentine spring coupling:...

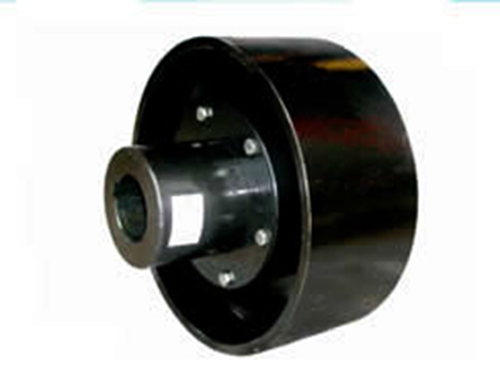

LLA tire coupling

LLA tire coupling is made as required...

LLA tire coupling

LLA tire coupling is made as required...

SWC universal coupling

SWC universal coupling can be widely used in smelting...

SWC universal coupling

SWC universal coupling can be widely used in smelting...

HLL type-elastic pin coupling

HLL type-elastic pin coupling is used if...

HLL type-elastic pin coupling

HLL type-elastic pin coupling is used if...