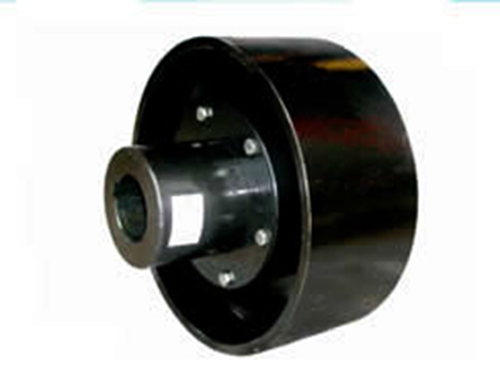

JQ type-jacket couplingIt uses two clamp shells split along the axial direction, which are clamped by bolts to realize the connection of the two shafts. The torque is transmitted by the friction between the two halves of the coupling surface, and the flat key is used for auxiliary connection.

JQ-type clamp housing coupling is composed of two clamp housings sectioned along the axial direction, mainly single groove and double groove, with key groove and without key groove, single groove clamp with single aperture and double aperture The holding type rigid coupling is tightly sleeved on the shaft, providing high torque grip without damaging the shaft surface.The double-slot rigid coupling is convenient for disassembly and maintenance, and there is no need to move other parts.The screws of the double-slot rigid coupling are installed in front and back to maintain dynamic balance.The raw materials are aluminum, carbon steel and stainless steel. There are a variety of models and specifications, and the double-aperture couplings with one end of metric and the other inch can also be customized according to the special requirements of customers.

During assembly and disassembly of the clamp housing coupling, the shaft does not need to move axially, so the assembly and disassembly is very convenient. The disadvantage of the clamp housing coupling is that the accuracy of the axis of the two shafts is low, the structure and shape are more complicated, and the manufacturing and balance accuracy is low. , It is only suitable for the occasions of low speed and stable load. Generally, the linear speed of the outer edge is not more than 5m/s. When the linear speed exceeds 5m/s, a balance check is required.

In order to balance the situation, the bolts should be installed between the forward and reverse phases. JQ type jacket coupling does not have axial, radial and angular compensation performance, simple structure, convenient assembly and disassembly, suitable for low speed (high circumferential speed of 5m/s), no impact, stable vibration load occasions It is suitable for the connection of vertical shafts such as agitators.

The main features of JQ type-jacket coupling:

1. Light weight, ultra-low inertia and high sensitivity;

2. Maintenance-free, oil resistance and resistance;

3. Eccentricity cannot be tolerated, and the shaft should be exposed as much as possible during use;

4. The main body material can be cast steel/stainless steel;

5. The fixing method includes clamping and top wire fixing;

6. Simple structure, easy to load and unload.

HLL type-elastic pin coupling

HLL type-elastic pin coupling is used if...

HLL type-elastic pin coupling

HLL type-elastic pin coupling is used if...

Keyway flange diaphragm coupling

The keyway flange diaphragm coupling depends on the diaphragm...

Keyway flange diaphragm coupling

The keyway flange diaphragm coupling depends on the diaphragm...

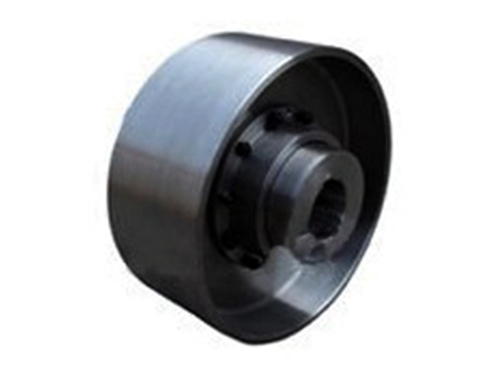

Brake wheel

The quality sales of brake wheels produced by our company...

Brake wheel

The quality sales of brake wheels produced by our company...

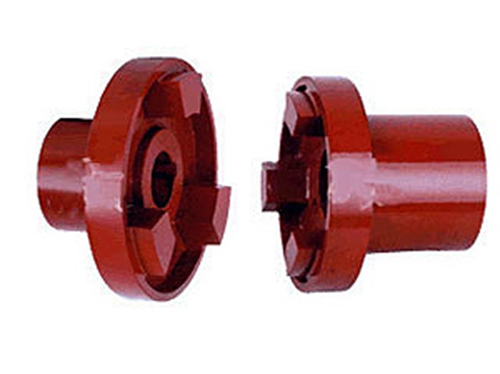

Three-jaw coupling for pump

The three-jaw coupling for pumps is a water pump coupling...

Three-jaw coupling for pump

The three-jaw coupling for pumps is a water pump coupling...