Z7C type expansion joint sleeveIt is a keyless coupling device between the shaft and the shaft sleeve. This device can apply clamping force to the shaft sleeve from the outside to form a mechanical compression fit between the shaft and the shaft sleeve to transmit torque. The expansion sleeve itself does not transmit any Moment torque and load.

Basic dimensions and parameters of Z7C type expansion sleeve:

| basic size | Socket head cap screws | Rated load | Screw Tighten Moment MA N · m |

Weight kg |

|||||||

| d | D | dn | l | H | e | d1 | n | Axial force F1 KN |

Torque M1 KN·m |

||

| mm | |||||||||||

| 140 | 230 | 95 | 60 | 74 | 7 | M12 × 55 | 12 | 436 | 20.7 | 100 | 13 |

| 100 | 480 | 24.0 | |||||||||

| 105 | 518 | 27.2 | |||||||||

| 155 | 263 | 105 | 66 | 80 | M12 × 60 | 15 | 545 | 28.6 | 20 | ||

| 110 | 591 | 32.5 | |||||||||

| 115 | 633 | 36.4 | |||||||||

| 165 | 290 | 115 | 72 | 88 | 8 | M16 × 65 | 10 | 701 | 40.3 | 240 | 26 |

| 120 | 758 | 45.5 | |||||||||

| 125 | 811 | 50.7 | |||||||||

| 175 | 300 | 125 | 832 | 52 | 29 | ||||||

| 130 | 880 | 57.2 | |||||||||

| 135 | 924 | 62.4 | |||||||||

| 185 | 330 | 135 | 92 | 112 | 10 | M16 × 80 | 15 | 1037 | 70 | 47 | |

| 140 | 1100 | 77 | |||||||||

| 145 | 1159 | 84 | |||||||||

| 200 | 350 | 145 | 1291 | 93 | 50 | ||||||

| 150 | 1353 | 101.5 | |||||||||

| 155 | 1409 | 109.2 | |||||||||

| 220 | 370 | 160 | 114 | 134 | M16 × 90 | 20 | 1625 | 130 | 240 | 65 | |

| 165 | 1703 | 140.5 | |||||||||

| 170 | 1776 | 151 | |||||||||

| 240 | 405 | 170 | 120 | 144 | 12 | M20 × 100 | 15 | 1835 | 156 | 470 | 87 |

| 180 | 1994 | 179.5 | |||||||||

| 190 | 2137 | 203 | |||||||||

| 260 | 430 | 190 | 136 | 160 | M20 × 110 | 16 | 2242 | 213 | 100 | ||

| 200 | 2390 | 239 | |||||||||

| 210 | 2542 | 265 | |||||||||

| 280 | 460 | 210 | 148 | 172 | M20 × 110 | 20 | 2686 | 282 | 132 | ||

| 220 | 2900 | 319 | |||||||||

| 230 | 3087 | 355 | |||||||||

| 300 | 485 | 230 | 152 | 176 | M20 × 120 | 2965 | 341 | 140 | |||

| 240 | 3175 | 381 | |||||||||

| 245 | 3273 | 401 | |||||||||

| 320 | 520 | 240 | 160 | 184 | M20 × 130 | 24 | 3317 | 398 | 165 | ||

| 250 | 3536 | 442 | |||||||||

| 260 | 3738 | 486 | |||||||||

| 340 | 570 | 250 | 176 | 200 | M24 × 130 | 20 | 4080 | 510 | 820 | 240 | |

| 260 | 4307 | 560 | |||||||||

| 270 | 4519 | 610 | |||||||||

| 360 | 590 | 280 | 180 | 204 | M24 × 140 | 4707 | 659 | 250 | |||

| 290 | 4931 | 715 | |||||||||

| 295 | 5044 | 744 | |||||||||

| 390 | 660 | 300 | 188 | 212 | M24 × 140 | 24 | 5733 | 860 | 350 | ||

| 310 | 5903 | 915 | |||||||||

| 320 | 6063 | 970 | |||||||||

| 420 | 690 | 330 | 214 | 238 | M24 × 150 | 28 | 6182 | 1020 | 410 | ||

| 340 | 6470 | 1100 | |||||||||

| 350 | 6743 | 1180 | |||||||||

| 460 | 770 | 360 | 224 | 252 | 14 | M27 × 170 | 24 | 7222 | 1300 | 1210 | 540 |

| 370 | 7514 | 1390 | |||||||||

| 380 | 7789 | 1480 | |||||||||

| 500 | 850 | 400 | 246 | 274 | M27 × 180 | 30 | 9400 | 1880 | 750 | ||

| 410 | 9659 | 1980 | |||||||||

| 420 | 9905 | 2080 | |||||||||

| Note: The mechanical performance grade of Z7C type expansion coupling set screws is 10.9. | |||||||||||

SWCCH coupling

SWCCH coupling is a common...

SWCCH coupling

SWCCH coupling is a common...

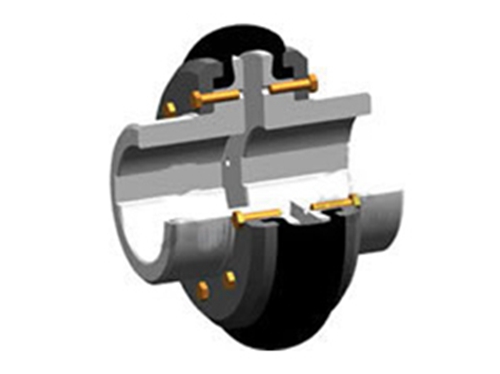

LLA tire coupling

LLA tire coupling is made as required...

LLA tire coupling

LLA tire coupling is made as required...

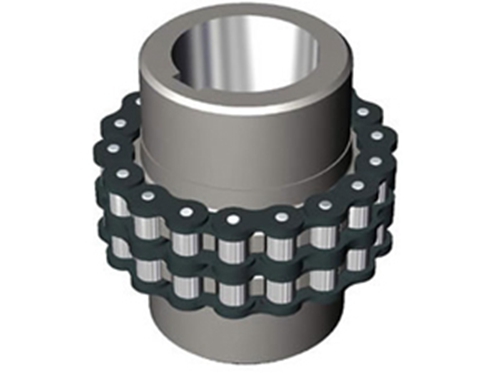

GL type roller chain coupling

GL type roller chain coupling has a simple structure...

GL type roller chain coupling

GL type roller chain coupling has a simple structure...

SWP_E universal coupling

SWP_E universal coupling due to its deviation angle...

SWP_E universal coupling

SWP_E universal coupling due to its deviation angle...