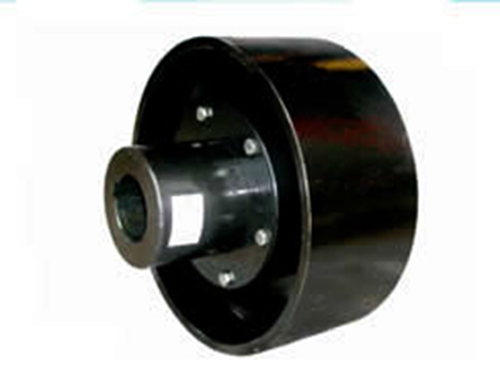

UL rubber coupling tire body, tire ringThe UL rubber coupling tire body and tire ring have a simple structure, convenient disassembly and maintenance, and no need for lubrication...

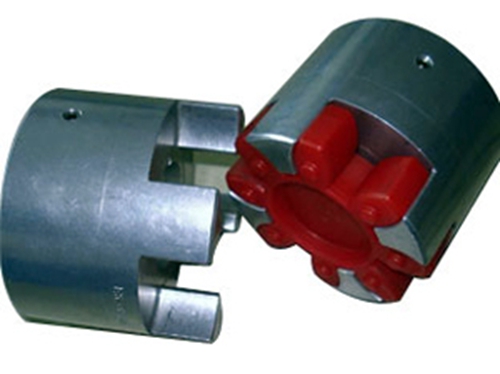

UL rubber coupling tire body, tire ringThe UL rubber coupling tire body and tire ring have a simple structure, convenient disassembly and maintenance, and no need for lubrication... ML plum blossom couplingML type plum blossom coupling has simple structure, small radial size, light weight, small moment of inertia, suitable for...

ML plum blossom couplingML type plum blossom coupling has simple structure, small radial size, light weight, small moment of inertia, suitable for... HLL type-elastic pin couplingHLL type-elastic pin coupling is a pin made of a number of non-metal elastic materials, placed in...

HLL type-elastic pin couplingHLL type-elastic pin coupling is a pin made of a number of non-metal elastic materials, placed in... Polyurethane plum-shaped elastomerPolyurethane plum-shaped elastomer is a plum-shaped elastic element made of polyurethane material, which...

Polyurethane plum-shaped elastomerPolyurethane plum-shaped elastomer is a plum-shaped elastic element made of polyurethane material, which... LXS star elastic couplingThe standard of Ever-PowerLXS star elastic coupling is JB/T 10466-2004, XLS series double flange type star elastic...

LXS star elastic couplingThe standard of Ever-PowerLXS star elastic coupling is JB/T 10466-2004, XLS series double flange type star elastic...The diaphragm coupling is composed of several groups of diaphragms that are interwoven and connected with two halves of the coupling with bolts. Each group of diaphragms is made up of several pieces. The diaphragms are divided into connecting rod type and whole piece type with different shapes.

The transmission efficiency of the diaphragm coupling is very high, up to 99.86%.Especially suitable for medium, high speed and high power transmission.

Couplings mainly include metal diaphragm couplings, serpentine spring couplings, hyperboloid gear couplings, elastomer couplings and other new flexible data couplings.For example, the metal diaphragm coupling uses the high fatigue resistance characteristics of the metal diaphragm material; so that the overall coupling has the advantages of light weight, reliable work, no need for smoothness, and convenient maintenance.

The diaphragm coupling relies on the elastic deformation of the diaphragm to compensate for the relative displacement of the connected two shafts. It is a high-performance flexible coupling with metal elastic elements. It does not need to be smooth, has a compact structure, has a long service life, and does not rotate. The gap is not affected by temperature and oil pollution, and has the characteristics of acid resistance, alkali resistance, and corrosion resistance. It is suitable for shaft transmission in high temperature, high speed, and corrosive medium conditions. It is generally used for shaft transmission of various mechanical installations, such as water pumps ( Especially high-power, chemical pumps), fans, compressors, hydraulic machinery, petroleum machinery, printing machinery, textile machinery, chemical machinery, mining machinery, metallurgical machinery, aviation (helicopters), naval high-speed power transmission systems, After balancing, it is more common to be applied to high-speed transmission shafts.

Compared with the gear coupling, the diaphragm coupling has no relative sliding, no need for smoothness, sealing, no noise, no maintenance at all, easier to manufacture, and can partially replace the gear coupling.Diaphragm couplings have been widely used in countries where the industry is booming. In practical applications, the intermediate shaft type is commonly used to improve the performance of two-axis offset compensation.

The diaphragm coupling can compensate for the axial, radial and angular deviations between the active machine and the driven machine due to manufacturing errors, installation errors, load-bearing deformations, and the effects of temperature rise changes.The diaphragm coupling is a flexible coupling with a metal elastic element. It relies on a metal coupling diaphragm to connect the main and driven machines to transmit torque. It has the advantages of elastic vibration reduction, no noise, and no need for lubrication. It is a substitute for drums today. It is an ideal product for gear couplings and general couplings.