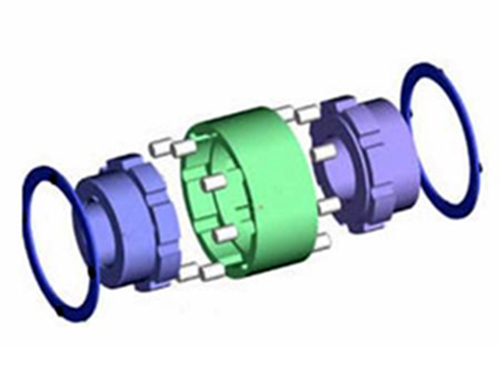

Z1 type expansion joint sleeveIt is composed of inner and outer cone rings.The structure is compact and light, suitable for occasions with small installation space.It can be used instead of various key connections or interference fit connections.In order to transfer larger loads, multiple pairs of expansion sleeves can be used. The single-sided compression does not exceed 4 pairs of rings, and the double-sided compression can reach 8 pairs of rings, and the neutrality is good.

The main purpose of the expansion coupling sleeve (referred to as the expansion sleeve) is to replace the coupling effect of single keys and splines to realize the coupling of mechanical parts (such as gears, flywheels, belt pulleys, etc.) to the shaft to transmit load, and its function is in use It is divided into two categories: expansion and locking.

|

basic size |

Rated load when P f =100N/mm 2 |

weight |

||||

|

d |

D |

L |

1 |

Axial force F 1 |

Torque M 1 |

|

|

mm |

||||||

|

20 |

25 |

6.3 |

5.3 |

4.0 |

0.004 |

0.01 |

|

22 |

26 |

4.5 |

0.005 |

0.01 |

||

|

25 |

30 |

5.0 |

0.06 |

0.01 |

||

|

28 |

32 |

5.6 |

0.08 |

0.01 |

||

|

30 |

35 |

6.0 |

0.09 |

0.01 |

||

|

32 |

36 |

6.4 |

0.10 |

0.01 |

||

|

35 |

40 |

7.0 |

6.0 |

8.2 |

0.15 |

0.02 |

|

40 |

45 |

8.0 |

6.6 |

9.9 |

0.20 |

0.02 |

|

45 |

52 |

10.0 |

8.6 |

14.6 |

0.33 |

0.04 |

|

50 |

57 |

16.2 |

0.40 |

0.05 |

||

|

55 |

62 |

17.8 |

0.49 |

0.05 |

||

|

60 |

68 |

12.0 |

10.4 |

23.5 |

0.70 |

0.07 |

|

65 |

73 |

25.6 |

0.83 |

0.08 |

||

|

70 |

79 |

14.0 |

12.2 |

32.0 |

1.12 |

0.11 |

|

75 |

84 |

34.4 |

1.29 |

0.12 |

||

|

80 |

91 |

17.0 |

15.0 |

45.0 |

1.81 |

0.19 |

|

85 |

96 |

48.0 |

2.04 |

0.20 |

||

|

90 |

101 |

51.0 |

2.29 |

0.22 |

||

|

95 |

106 |

54.0 |

2.55 |

0.23 |

||

|

100 |

114 |

21.0 |

18.7 |

70.0 |

3.50 |

0.38 |

|

105 |

119 |

73.2 |

3.82 |

0.40 |

||

|

110 |

124 |

77.0 |

4.25 |

0.41 |

||

|

120 |

134 |

84.0 |

5.05 |

0.45 |

||

|

125 |

139 |

92.0 |

5.75 |

0.62 |

||

|

130 |

148 |

28.0 |

25.3 |

124.0 |

8.05 |

0.85 |

|

140 |

158 |

134.0 |

9.35 |

0.91 |

||

|

150 |

168 |

143.0 |

10.70 |

0.97 |

||

|

160 |

178 |

152.5 |

12.20 |

1.02 |

||

|

170 |

191 |

33.0 |

30.0 |

192.0 |

16.30 |

1.50 |

|

180 |

201 |

204.0 |

18.30 |

1.58 |

||

|

190 |

211 |

214.0 |

20.40 |

1.68 |

||

|

200 |

224 |

38.0 |

34.8 |

262.0 |

26.20 |

2.32 |

|

210 |

234 |

275 |

28.90 |

2.45 |

||

|

220 |

244 |

288.0 |

37.70 |

2.49 |

||

|

240 |

267 |

42.0 |

39.5 |

358.0 |

43.00 |

3.52 |

|

250 |

280 |

48.0 |

44.0 |

415 |

52.00 |

4.68 |

|

260 |

290 |

435.0 |

56.50 |

4.82 |

||

|

280 |

313 |

53.0 |

49.0 |

520.0 |

72.50 |

6.27 |

|

300 |

333 |

555.0 |

83.00 |

6.47 |

||

|

320 |

360 |

65.0 |

59.0 |

710.0 |

114.00 |

10.90 |

|

340 |

380 |

755 |

128.50 |

11.50 |

||

|

360 |

400 |

800 |

144.00 |

12.20 |

||

|

380 |

420 |

845 |

160.50 |

12.80 |

||

|

400 |

440 |

890 |

178.00 |

13.50 |

||

|

420 |

460 |

935 |

196.00 |

14.10 |

||

|

450 |

490 |

998.0 |

224.50 |

15.20 |

||

|

480 |

520 |

1070.0 |

256.00 |

16.00 |

||

|

500 |

540 |

1110.0 |

278.00 |

16.50 |

||

UL tire coupling

UL tire coupling is the use of tire...

UL tire coupling

UL tire coupling is the use of tire...

SWCBF flange coupling

SWCBF flange coupling is used to connect...

SWCBF flange coupling

SWCBF flange coupling is used to connect...

ZLD type elastic pin gear coupling

ZLD type elastic pin gear coupling is advantageous...

ZLD type elastic pin gear coupling

ZLD type elastic pin gear coupling is advantageous...

High-speed diaphragm coupling

The high-speed diaphragm coupling consists of several sets of diaphragms (...

High-speed diaphragm coupling

The high-speed diaphragm coupling consists of several sets of diaphragms (...