GICL drum gear couplingBecause the angular compensation of drum gear couplings is greater than that of straight gear couplings, drum gear couplings are widely used. Straight gear couplings are obsolete products, and those who choose them should try not to use them.

Gear coupling is composed of internal gear ring with the same number of teeth and flange half coupling with external teeth.The external teeth are divided into two types: straight teeth and drum teeth. The so-called drum teeth means that the external teeth are made into a spherical surface. The spherical surface is on the gear axis. The tooth side clearance is larger than that of ordinary gears.Gear couplingAllows larger angular displacement (compared to spur gear couplings), can adjust the contact conditions of the teeth, improve the torque transmission capacity, and prolong the service life.

| model | Nominal torque Tn N · m |

Allowable speed [n] r / min |

Diameter of shaft hole | Length of shaft hole | D | H | A | C | Moment of inertia kg.㎡ |

Grease consumption mL |

质量 Kg |

| Y,J1 | |||||||||||

| d1,d2 | L | ||||||||||

| GIICL1 | 355 | 4000 | 14-35 | 38-82 | 103 | 2.0 | 36 | 8 | 0.0035-0.00375 | 51 | 3.1 |

| GIICL2 | 630 | 4000 | 16-45 | 38-112 | 115 | 2.0 | 42 | 8 | 0.00550-0.00675 | 70 | 3.5 |

| GIICL3 | 1000 | 4000 | 22-56 | 38-112 | 127 | 2.0 | 44 | 8 | 0.010-0.0113 | 68 | 7.0 |

| GIICL4 | 1600 | 4000 | 38-65 | 60-142 | 149 | 2.0 | 49 | 8 | 0.02-0.0245 | 87 | 12.2 |

| GIICL5 | 2800 | 4000 | 40-75 | 84-142 | 167 | 2.5 | 55 | 10 | 0.0378-0.0433 | 125 | 18.0 |

| GIICL6 | 4500 | 4000 | 45-90 | 84-172 | 187 | 2.5 | 56 | 10 | 0.0663-0.0843 | 148 | 26.5 |

| GIICL7 | 6300 | 3750 | 50-105 | 84-212 | 204 | 3.5 | 60 | 10 | 0.103-0.151 | 175 | 39.2 |

| GIICL8 | 9000 | 3300 | 55-115 | 84-212 | 230 | 3.0 | 67 | 12 | 0.167-0.241 | 268 | 49.7 |

| GIICL9 | 14000 | 3000 | 60-135 | 107-252 | 256 | 3.0 | 69 | 12 | 0.316-0.470 | 310 | 79.6 |

| GIICL10 | 20000 | 2650 | 65-150 | 107-252 | 287 | 3.5 | 78 | 14 | 0.511-0.745 | 472 | 101 |

| GIICL11 | 31500 | 2350 | 70-175 | 107-302 | 325 | 3.5 | 81 | 14 | 1.096-1.588 | 550 | 161 |

| GIICL12 | 45000 | 2100 | 75-200 | 107-352 | 362 | 4.0 | 89 | 16 | 1.623-3.055 | 695 | 213 |

| GIICL13 | 63000 | 1850 | 150-225 | 202-352 | 412 | 4.5 | 98 | 18 | 3.925-4.918 | 1019 | 315 |

| GIICL14 | 100000 | 1650 | 170-250 | 242-410 | 462 | 5.5 | 172 | 22 | 8.025-9.725 | 3900 | 476 |

| GIICL15 | 160000 | 1500 | 190-285 | 282-470 | 512 | 5.5 | 182 | 22 | 14.300-17.45 | 3700 | 696 |

| GIICL16 | 224000 | 1300 | 220-320 | 282-470 | 580 | 7.0 | 209 | 28 | 23.925-29.1 | 4500 | 913 |

| GIICL17 | 315000 | 1200 | 250-365 | 330-550 | 644 | 7.0 | 198 | 28 | 43.095-53.725 | 4900 | 1322 |

| GIICL18 | 450000 | 1050 | 280-400 | 380-650 | 726 | 8.0 | 222 | 28 | 78.525-99.500 | 7000 | 1948 |

| GIICL19 | 630000 | 950 | 300-470 | 380-650 | 818 | 8.0 | 232 | 32 | 136.750-175.5 | 8900 | 3026 |

| GIICL20 | 900000 | 800 | 360-540 | 450-800 | 928 | 10.5 | 247 | 32 | 261.75-360.75 | 11000 | 3984 |

| GIICL21 | 1250000 | 750 | 400-600 | 540-800 | 1022 | 11.5 | 255 | 40 | 468.75-561.50 | 13000 | 4977 |

| GIICL22 | 1600000 | 650 | 450-680 | 540-800 | 1134 | 13.0 | 262 | 40 | 753.750-904.750 | 16000 | 7738 |

| GIICL23 | 2240000 | 600 | 500-770 | 680-800 | 1282 | 14.5 | 299 | 50 | 1517-1725 | 28000 | 10783 |

| GIICL24 | 3150000 | 550 | 560-880 | 680-900 | 1428 | 16.5 | 317 | 50 | 2486-3131.75 | 33000 | 15015 |

| GIICL25 | 4000000 | 460 | 670-1040 | 900-1000 | 1644 | 19.0 | 325 | 50 | 5174.25-7198.25 | 43000 |

LLB tire coupling

LLB tire coupling is a high elastic...

LLB tire coupling

LLB tire coupling is a high elastic...

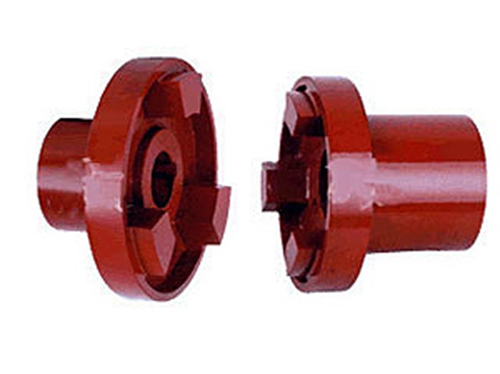

Three-jaw coupling for pump

The three-jaw coupling for pumps is a water pump coupling...

Three-jaw coupling for pump

The three-jaw coupling for pumps is a water pump coupling...

LX star elastic coupling

Ever-PowerLX star flexible coupling is designed to...

LX star elastic coupling

Ever-PowerLX star flexible coupling is designed to...

DJM expansion sleeve diaphragm coupling

The DJM expansion sleeve diaphragm coupling passes through the diaphragm...

DJM expansion sleeve diaphragm coupling

The DJM expansion sleeve diaphragm coupling passes through the diaphragm...