[一], the treatment of the misalignment of the fan and the motor coupling

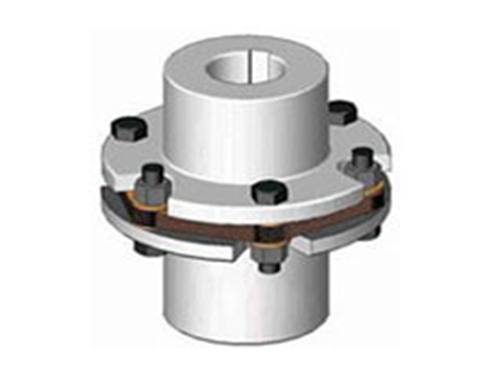

The fan and the motor are connected by a quincunx coupling to transmit movement and torque.Misalignment is a common failure of fans, and 60% of fan failures are related to misalignment.The misalignment fault of the fan refers to the degree of inclination or deviation between the axis line of the two rotors of the fan and the motor and the center line of the bearing.The main reasons for the misalignment of the fan rotor system:

(1) The bearing air gap is too large or the ball is slightly corroded. This situation is generally caused by insufficient lubrication or poor oil quality. This situation can easily cause misalignment and vibration. The bearing should be replaced according to the situation.

(2) Long-term vibration of the bearing seat causes deviation.Vibration of a large fan is inevitable, so it is easy to cause the base fastening bolts to loosen slightly, and the consequence is to cause misalignment and vibration.

Bearing seat installation standard: the longitudinal and transverse centerline deviation of the bearing seat is ±0.5mm.The horizontal tolerance of the bearing seat is 0.1/1000.The longitudinal levelness of the two bearing seats should then be based on the axial levelness of the rotor.The bearing seat and the base bolts should be tightly fitted after being tightened, and check with a 0.05mm feeler gauge to not be inserted.

(3) Caused by the main motor itself.Large motors have higher requirements for dynamic balance. Due to various reasons, the motor itself is damaged due to various reasons and requires misalignment.After the fan rotor system has a misalignment fault, a series of dynamic effects that are unfavorable to the operation of the equipment will be generated during the rotation process, which will cause the deflection of the coupling, the wear of the bearing, the steady state of the oil film, and the deflection and deformation of the shaft. The force and the additional force on the bearing cause the abnormal vibration of the fan and the early damage of the bearing, which is harmful.For the fan misalignment fault.

At present, we generally adopt primitive methods to deal with it.First find the level of the main shaft of the fan, and rotate the impeller, the level deviation of the main shaft of the fan at each point is within the range; then find the alignment of the fan and the motor coupling, generally using a dial indicator, divided into 4 points Detect the beating degree, the beating degree of 4 points is within the technical range, so that the middle degree is basically found.The solution can be solved with a laser alignment instrument, which is convenient.Vibration treatment caused by impeller imbalance

When the crane is working, the misalignment of the coupling between the reducer and the motor of the hoisting mechanism and the luffing mechanism, or the shaft between the two due to excessive installation errors, will cause the vibration of the machine, the wear of the bearing and the shaft Deflection and deformation will cause the high-speed shaft of the reducer to break in serious cases, which poses a great threat to the normal operation of the system. From the recent several accidents of the crane reducer shaft broken, it may be caused by such factors. of.

[二], the nature of the tower crane installation inspection

As the urbanization process is getting faster and faster, the scale of engineering projects is getting bigger and bigger, and tower cranes have gradually become important lifting equipment for modern engineering and civil engineering.Through the work of the tower crane, the waste of manpower and material resources is reduced, and the engineering efficiency is improved.

However, tower cranes belong to high-rise work, which is dangerous.Therefore, relevant departments need to realize its importance, strengthen the installation and inspection of tower cranes, and the normal operation of machinery and equipment.

Since the economic reform, our country has continued to take basic measures in urban engineering. With the increase of large construction projects, the use of large-scale machinery and equipment has become more frequent. Among them, tower cranes are used very frequently, and drum gear couplings In large-scale construction projects, tower cranes are one of the indispensable mechanical equipment in construction.Although the use of large-scale equipment has improved the work efficiency of construction projects, reduced labor costs, and the development of construction projects, due to the existence of large-scale machinery and equipment, if the tower crane installation and inspection work is unqualified, it may be possible during the operation of the equipment. It may cause damage to machinery and equipment, and may even directly threaten the lives of workers, increase the maintenance of machinery and equipment, and may cause casualties, seriously affecting the construction progress of the construction project and the overall economic efficiency of the project.Therefore, the strict implementation of the installation and inspection of tower cranes is conducive to the construction of construction projects, improves the quality of construction projects and the clean space, and thereby enhances the competitiveness of enterprises.

DL polygonal rubber couplingDL Polygonal Rubber Coupling is made of rubber material, made into a 6-angle (or octagonal) shape with a circular cross-section...

DL polygonal rubber couplingDL Polygonal Rubber Coupling is made of rubber material, made into a 6-angle (or octagonal) shape with a circular cross-section... GⅡCLZ drum gear couplingThe GⅡCLZ drum gear coupling is composed of an inner gear ring with the same number of teeth and a flange semi-coupling with external teeth...

GⅡCLZ drum gear couplingThe GⅡCLZ drum gear coupling is composed of an inner gear ring with the same number of teeth and a flange semi-coupling with external teeth... Stainless steel elastic coupling JZM typeThe stainless steel elastic coupling JZM type is a large torque diaphragm coupling for the shaft connection of heavy machinery and equipment...

Stainless steel elastic coupling JZM typeThe stainless steel elastic coupling JZM type is a large torque diaphragm coupling for the shaft connection of heavy machinery and equipment... WGT gear couplingWhen the WGT gear coupling is working, the two shafts produce relative angular displacement, and the tooth surfaces of the inner and outer teeth are periodically...

WGT gear couplingWhen the WGT gear coupling is working, the two shafts produce relative angular displacement, and the tooth surfaces of the inner and outer teeth are periodically... YL type flange couplingYL type flange coupling is abbreviated as flange coupling, which belongs to rigid coupling, which is a combination of two convex...

YL type flange couplingYL type flange coupling is abbreviated as flange coupling, which belongs to rigid coupling, which is a combination of two convex...