JSP type serpentine spring couplingJSP type serpentine spring coupling product features: good vibration damping, long service life, bearing variable load...

JSP type serpentine spring couplingJSP type serpentine spring coupling product features: good vibration damping, long service life, bearing variable load... GY, GYS, GYH type couplingThe surface roughness of GY, GYS, GYH couplings refers to the small spacing and...

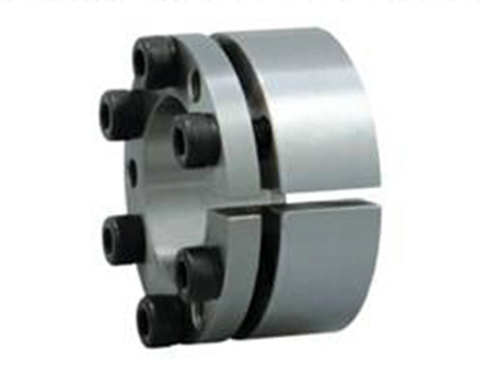

GY, GYS, GYH type couplingThe surface roughness of GY, GYS, GYH couplings refers to the small spacing and... Z3 type expansion coupling sleeveThe characteristics of the Z3 type expansion coupling sleeve: The Z3 type expansion inner and outer cone rings are tightened with inner hexagonal bolts, which can transmit more...

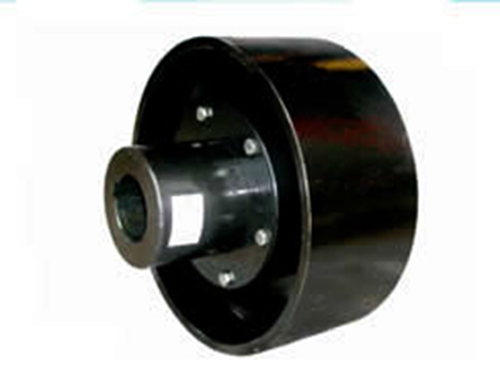

Z3 type expansion coupling sleeveThe characteristics of the Z3 type expansion coupling sleeve: The Z3 type expansion inner and outer cone rings are tightened with inner hexagonal bolts, which can transmit more... ZLL elastic pin gear couplingThe basic parameters and important measurement of ZLL elastic pin gear coupling are used for a lot of non-metallic materials...

ZLL elastic pin gear couplingThe basic parameters and important measurement of ZLL elastic pin gear coupling are used for a lot of non-metallic materials... HLL type-elastic pin couplingHLL type-elastic pin coupling is a pin made of a number of non-metal elastic materials, placed in...

HLL type-elastic pin couplingHLL type-elastic pin coupling is a pin made of a number of non-metal elastic materials, placed in...The quality of the coupling is not only the conformity of the external dimensions and structural form, but also the internal quality (comprehensive performance indicators such as strength and fatigue strength).Chemicals, machinery, ore, aerospace, shipbuilding, metallurgy and even household appliances used in daily life are inseparable from transmission systems. Standards have specific industry standards for various transmission systems, such as the width of elevator pedals and pedals. Thickness and connection clearance, material and corresponding heat treatment process, these indexes are often required by specific standards.But often the standard is a selection range standard. For example, the material selection can be 45#, 40CR, or 42CRMO, and the heat treatment requirement is a range. For example, the tooth surface hardness of the drum gear coupling is HRC40-50.Of course, if it is a strict implementation standard, the materials and corresponding heat treatment according to the customer's working conditions are within the standard range, and there is no problem.Coupling manufacturing is embodied in the standard based on the selection of reasonable materials (casting, forging materials) and the corresponding heat treatment process according to the actual use conditions of the customer, the modulus of the gear coupling is determined, and the tooth side clearance Determine, tooth width and tooth meshing position, etc., diaphragm coupling manufacturing is reflected in material and heat treatment, dynamic balance accuracy, connecting bolt matching accuracy and bolt strength (level 8.8, 10.9, 12.9), diaphragm material selection And manufacturing.The overall performance stability of the transmission system is a key factor related to the service life and use cost of the entire set of equipment, and even a major event related to life and property. Of course, the comprehensive performance of the entire set of equipment is a comprehensive requirement for the entire components.