CLZ type gear couplingThe external teeth are divided into straight teeth and drum teeth. The so-called drum teeth means that the external teeth are made into a spherical surface. The spherical surface is on the gear axis. The tooth side clearance is larger than that of ordinary gears. Drum-shaped gear couplings allow Larger angular displacement (compared to spur gear couplings), the contact conditions of the teeth can be improved, the torque transmission capacity is improved, and the service life is prolonged.The contact state along the tooth width when there is angular displacement.With the development of China’s economy, the demand for large-diameter pipe rolling mills has increased, and the requirements for couplings used in the main drive have also become higher. The couplings that meet this requirement include cross universal couplings and large torque drums Gear couplings, the torque of the cross universal coupling can be reached, but the impact bearing performance is poor and the life is short, which is a big disadvantage; the current standard couplings used in domestic rolling mills cannot meet the requirements. Only reach 1/2 to 1/3 of the required transfer torque, the coupling manufacturer can meet the requirements, but because it uses specialized technology, coupled with the difficulty of manufacturing, so the price is very expensive.A pipe rolling mill requires about 10 sets, and the cost of outsourcing spare parts is very high.The various drum-shaped gear couplings developed by German Lingsi Coupling Factory according to customer needs have been able to meet the needs of domestic manufacturers.

When CLZ type gear coupling is working, the two shafts produce relative angular displacement, and the tooth surfaces of the internal and external teeth periodically slide relative to each other in the axial direction, which will inevitably cause tooth surface wear and power consumption. Therefore, the gear coupling needs to be Work in a good and sealed state.Gear couplings have small radial dimensions and large load-bearing capacity. They are often used in shaft transmissions under low-speed and heavy-duty conditions. The dynamically balanced gear couplings can be used for high-speed transmissions, such as gas turbine shaft transmissions.Because the angular compensation of the drum gear coupling is greater than that of the straight gear coupling.

CLZ typeGear couplingThe bearing impact performance is good, but the tooth surface contact stress and tooth root bending fatigue strength are required. If we adopt the structure, material, and technology, then the coupling can meet the requirements of large diameter pipe rolling mills. CLZ type gear coupling: gear coupling is a rigid-flexible coupling. The gear coupling is composed of an inner gear ring with the same number of teeth and a flange half coupling with external teeth.

SWC_WH coupling

Universal coupling big features...

SWC_WH coupling

Universal coupling big features...

Z4 type expansion joint sleeve

The comparison between Z4 type expansion joint sleeve and Z2 type...

Z4 type expansion joint sleeve

The comparison between Z4 type expansion joint sleeve and Z2 type...

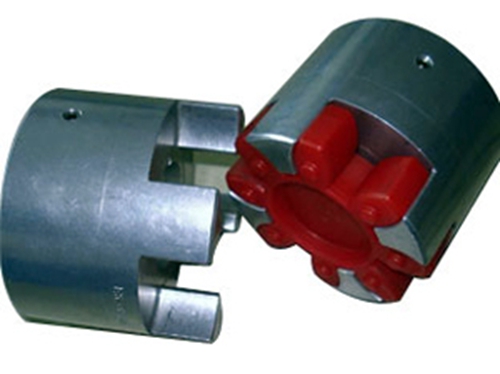

LXS star elastic coupling

The standard of Ever-PowerLXS star elastic coupling...

LXS star elastic coupling

The standard of Ever-PowerLXS star elastic coupling...

ZL type elastic pin gear coupling

ZL type elastic pin gear coupling is advantageous...

ZL type elastic pin gear coupling

ZL type elastic pin gear coupling is advantageous...