LXP star couplingLXP star coupling is made of engineering plastics as elastic elements, suitable for connecting two coaxial cables...

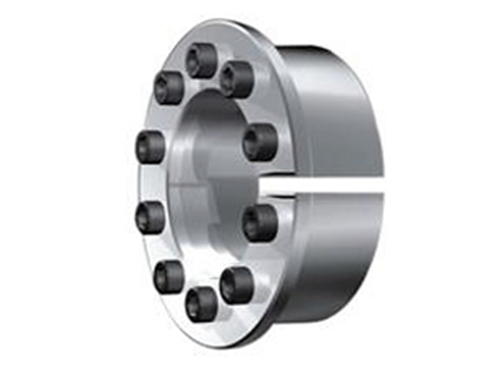

LXP star couplingLXP star coupling is made of engineering plastics as elastic elements, suitable for connecting two coaxial cables... Z15 type expansion joint sleeveThe Z15 type expansion coupling sleeve is suitable for the occasions that require high rotation accuracy and transmit large loads. ...

Z15 type expansion joint sleeveThe Z15 type expansion coupling sleeve is suitable for the occasions that require high rotation accuracy and transmit large loads. ... Stainless steel couplingThe stainless steel coupling is used to connect two shafts (the driving shaft and the driven shaft) in different mechanisms...

Stainless steel couplingThe stainless steel coupling is used to connect two shafts (the driving shaft and the driven shaft) in different mechanisms... Z16 type expansion joint sleeveThe variety and quality of Z16 expansion joint sleeves are stable.The company's equipment, technology...

Z16 type expansion joint sleeveThe variety and quality of Z16 expansion joint sleeves are stable.The company's equipment, technology... Z2 type expansion sleeveThe Z2 type expansion sleeve consists of an open double cone inner ring, an open double cone outer ring and two double cone...

Z2 type expansion sleeveThe Z2 type expansion sleeve consists of an open double cone inner ring, an open double cone outer ring and two double cone...Nowadays, all kinds of couplings have their own standards. The new standard has made corresponding increases in the specifications, materials and dimensions of the couplings on the basis of the original, in order to meet the requirements of different working conditions, and expand the size of the couplings. Scope of application.

When installing the coupling, the user considers the actual situation of the coupling and related installation factors, and the correct installation can only ensure the normal operation and service life of the coupling.

XNUMX. First, consider that under the influence of manufacturing, installation, load, temperature change and other conditions of the coupling, it is difficult for the installed coupling to accurately align the two shafts. If the radial displacement is relatively large, you can choose the slider coupling If the angular displacement is relatively large, choose a universal coupling.

Second, consider the working speed and centrifugal force of the equipment. If it is a high-speed drive shaft, install a coupling with higher balance accuracy, such as a diaphragm coupling, but do not choose a coupling with eccentricity.

XNUMX. After considering the size and nature of the torque that the equipment actually needs to transmit, as well as the requirements for the function of damping vibration, the installation of the coupling should also be cautious.Gear couplingIf it is a transmission device for severe impact load, it is more suitable to install a tire coupling.

In short, when installing the coupling, consider the factors that affect the installation of the coupling, and install the coupling correctly to play the role of the coupling.