HLL type-elastic pin couplingHLL type-elastic pin coupling is a pin made of a number of non-metal elastic materials, placed in...

HLL type-elastic pin couplingHLL type-elastic pin coupling is a pin made of a number of non-metal elastic materials, placed in... SWCWF flange type universal couplingSWCWF flange type universal coupling, especially the improved type (the first five types in Table 1) and other structures...

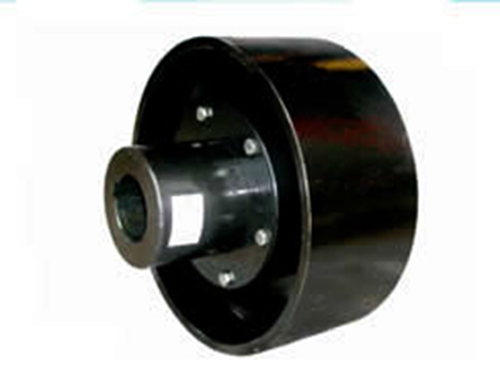

SWCWF flange type universal couplingSWCWF flange type universal coupling, especially the improved type (the first five types in Table 1) and other structures... WGZ type gear couplingEver-PowerWGZ type gear coupling structure, flexible operating mechanism, is worth choosing.My company has finished...

WGZ type gear couplingEver-PowerWGZ type gear coupling structure, flexible operating mechanism, is worth choosing.My company has finished... TGL type drum gear couplingTGL type drum gear couplings are mainly used in small and medium torque industrial and mining environments, such as fans, water...

TGL type drum gear couplingTGL type drum gear couplings are mainly used in small and medium torque industrial and mining environments, such as fans, water... Z20 type expansion joint sleeveThe Z20 type expansion joint sleeve has good interchangeability and excellent quality. It is the main...

Z20 type expansion joint sleeveThe Z20 type expansion joint sleeve has good interchangeability and excellent quality. It is the main...Diaphragm couplings rely on metal diaphragms to transmit torque and absorb deformation caused by misalignment. There is no relative movement between parts and there is no friction/wear, so it does not need lubrication, which is in line with the development direction of oil-free process equipment.The gear coupling is a rigid movable coupling. It relies on the relative slippage between the tooth surfaces to compensate for the misalignment of the two shafts. Therefore, the gear coupling should be lubricated, and the lubrication condition determines the gear coupling The key to good or bad work.Especially in high-speed operation, it appears to be prominent, such as the separation and leakage of oil under the action of centrifugal force, as well as the selection of lubricating oil, often because the lubrication design uses the bearing lubricating oil of the connected machine instead of the suitable load capacity Gear lubricants.Therefore, the lubrication problem of high-speed gear couplings is particularly prominent.On the other hand, the wear caused by the relative slippage of the tooth surface will cause a series of problems such as sludge and imbalance.Therefore, although gear couplings were once the choice for high-speed and high-power applications, with the emergence and development of diaphragm couplings, gear couplings have gradually faded out.

The diaphragm coupling uses a metal diaphragm as an elastic element, which has a large load transfer capacity, and there are no non-metal parts in the whole product, no aging problem, long service life, and it is suitable for harsh use environments.This is a non-metallic elastic element coupling.

The diaphragm coupling adopts austenitic stainless steel diaphragm, which can withstand large deformations while transmitting torsion, thereby compensating for the misalignment of the two shafts.The non-metal elastic coupling is restricted by the low strength and easy aging of the non-metal elastic element, which not only has a short life, but also has a small compensation ability.The gear coupling is restricted by the relative sliding speed of the tooth surface and the lubrication conditions (information, the relative sliding speed of the tooth surface should not be greater than 0.12 m/s), and the angular compensation ability is very small.Therefore, non-metal elastic couplings and gear couplings require higher installation and alignment.Once the misalignment exceeds the allowable range, it will cause the coupling to fail.

Features and advantages of diaphragm coupling:

XNUMX. The technical support is timely and sufficient, and the coupling selection can be matched with the unit to achieve the best use effect.Using domestic manufacturers’ products, both parties can communicate directly during the unit design process and fully negotiate on performance parameters, structural dimensions, etc.Moreover, this kind of communication is more direct and efficient, which can save time and improve design efficiency.

XNUMX. After-sales service response, especially the supply cycle of spare parts has been greatly shortened.State suppliers have a short production and delivery cycle, and can flexibly respond to changes in demand, and can respond to emergency needs.In recent years, the service awareness of various manufacturers has been significantly strengthened, and service capabilities and service quality have been continuously improved.

XNUMX. The product price advantage is obvious, especially the price of spare parts is very low.Under normal circumstances, the price of domestic diaphragm couplings is only a fraction of the price.For the host manufacturer, it can reduce the cost of the complete set, and for the end user, it can obtain technical support and spare parts supply at a very low price in the subsequent operation.