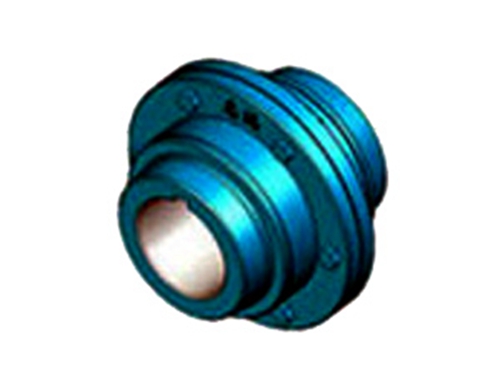

JSZ serpentine spring couplingIt is a structured metal elastic coupling.Due to the performance of the reed, the resonance phenomenon between the prime mover and the working machine is largely avoided, and the service life is much longer than that of the non-metal elastic element coupling; the tooth surface contacted by the reed is arc-shaped, and the size of the contact surface It varies with the size of the transmitted torque, so it can withstand large load changes. It is determined that its short-term overload capacity is 2 to 3 times the rated torque, and the transmission efficiency is 99.5%.

The various standard and non-standard couplings and various non-standard equipment accessories produced by our company are well received by users.It has provided strong technical and equipment support for the domestically produced couplings of many domestic coupling companies, and has won unanimous praise from the majority of users.

Nylon sleeve inner gear ring

The nylon inner gear ring is made of a flange with external teeth...

Nylon sleeve inner gear ring

The nylon inner gear ring is made of a flange with external teeth...

WGCⅡVertical Gear Coupling

Our company's WGCⅡ vertical gear coupling...

WGCⅡVertical Gear Coupling

Our company's WGCⅡ vertical gear coupling...

Z12C type expansion joint sleeve

Z12C type expansion coupling sleeve is suitable for shaft and shaft...

Z12C type expansion joint sleeve

Z12C type expansion coupling sleeve is suitable for shaft and shaft...

CL type gear coupling

CL type gear coupling belongs to removable rigid...

CL type gear coupling

CL type gear coupling belongs to removable rigid...