my companyLMZ-I plum-shaped elastic couplingWork stably, with good vibration damping, buffering and electrical insulation properties.The coupling does not need to be lubricated, the maintenance workload is small, and it can run continuously for a long time.

LMZ-I quincunx-shaped elastic coupling is mainly composed of two protruding teeth that are closely meshed and subjected to radial compression to transmit torque. When the two axes are relatively offset, the elastic element undergoes corresponding elastic deformation, which plays a role of automatic compensation. . LMZ-I plum-shaped elastic coupling is mainly suitable for frequent starting, forward and reverse rotation, medium and high speed, medium torque and high-demand working occasions, such as: metallurgy, mining, petroleum, chemical industry, lifting, transportation, light industry, Textiles, water pumps, fans, etc.Working environment temperature -35℃~+80℃, transmission nominal torque 25~12500Nm, allowable speed 1500~15300r/min.

Ever-PowerLMZ-IPlum couplingThe structure is simple, the radial dimension is small, the weight is light, and the moment of inertia is small. It is suitable for medium and high speed occasions.

| model | Permissible torque MP/(N·m) | Allowable speed mp/(r·min) | Diameter of shaft hole d1/mm, d2/mm, d3/mm |

Length of shaft hole | L0 mm |

D0 mm |

B mm |

D mm |

D1 mm |

d0 mm |

h mm |

Moment of inertia kg·m2 |

质量 kg |

Allowable displacement | |||||

| Elastic part hardness HA | Y type | J, Z type | |||||||||||||||||

| ≥75 | ≥85 | ≥94 | L mm |

L1 mm |

Radial mm |

Axial mm |

Angular | ||||||||||||

| MLL4-Ⅰ-160 | 140 | 250 | 400 | 4750 | 25,28 | 62 | 44 | 151 | 160 | 70 | 105 | 72 | 100 | 20 | 2.0 | 8.5 | 0.8 | 2.5 | 2°00` |

| 30,32,35,38 | 82 | 60 | 191 | ||||||||||||||||

| 40,42 | 112 | 84 | 251 | ||||||||||||||||

| MLL4-Ⅰ-200 | 3800 | 25,28 | 62 | 44 | 151 | 200 | 85 | 3.8 | 9.5 | ||||||||||

| 30,32,35,38 | 82 | 60 | 191 | ||||||||||||||||

| 40,42 | 112 | 84 | 251 | ||||||||||||||||

| MLL5-Ⅰ-200 | 250 | 400 | 800 | 3800 | 30,32,35,38 | 82 | 60 | 197 | 200 | 85 | 125 | 90 | 122 | 25 | 5.75 | 13.8 | 1.0 | 3.0 | 1°30` |

| 40,42,45,48 | 112 | 84 | 257 | ||||||||||||||||

| MLL6-Ⅰ-200 | 400 | 630 | 1120 | 3800 | 35,38 | 82 | 60 | 203 | 200 | 85 | 145 | 104 | 140 | 30 | 6.70 | 16.7 | |||

| 40,42,45,48,50,55 | 112 | 84 | 263 | ||||||||||||||||

| MLL6-Ⅰ-250 | 3050 | 35,38 | 82 | 60 | 203 | 250 | 105 | 13.50 | 21.7 | ||||||||||

| 40,42,45,48,20,55 | 112 | 84 | 263 | ||||||||||||||||

| MLL7-Ⅰ-250 | 710 | 1120 | 2240 | 3050 | 45,48,50,55 | 112 | 84 | 265 | 250 | 105 | 170 | 130 | 166 | 30 | 15.25 | 26.3 | 3.5 | ||

| 60,63,55 | 142 | 107 | 325 | ||||||||||||||||

| MLL7-Ⅰ-315 | 710 | 1120 | 2240 | 2400 | 45,48,50,55 | 112 | 84 | 265 | 315 | 135 | 170 | 35.0 | 34.7 | ||||||

| 60,63,65,70,71,75 | 142 | 107 | 325 | ||||||||||||||||

| MLL8-Ⅰ-315 | 1120 | 1800 | 3550 | 2400 | 50,55 | 112 | 84 | 272 | 315 | 135 | 200 | 156 | 196 | 35 | 45.9 | 47.3 | 1.5 | 4.0 | |

| 60,63,65,70,71,75 | 142 | 107 | 332 | ||||||||||||||||

| MLL8-Ⅰ-400 | 1900 | 50,55 | 112 | 84 | 272 | 400 | 170 | 98.0 | 61.3 | ||||||||||

| 60,63,65,70,71,75 | 142 | 107 | 332 | ||||||||||||||||

| MLL9-Ⅰ-400 | 1800 | 2800 | 5600 | 1900 | 60,63,65,70,71,75 | 142 | 107 | 334 | 400 | 170 | 230 | 180 | 225 | 35 | 132.5 | 84 | 4.5 | 1°00` | |

| 80,85,90,95 | 172 | 132 | 394 | ||||||||||||||||

| MLL9-Ⅰ-500 | 1800 | 2800 | 5600 | 1500 | 60,63,65,70,72,75 | 142 | 107 | 334 | 500 | 210 | 230 | 270 | 108 | ||||||

| 80,85,90,95 | 172 | 132 | 394 | ||||||||||||||||

| MLL10-Ⅰ-500 | 2800 | 4500 | 9000 | 1500 | 70,71,75 | 142 | 107 | 344 | 500 | 210 | 260 | 205 | 255 | 45 | 330 | 132 | 5.0 | ||

| 80,85,90,95 | 172 | 132 | 394 | ||||||||||||||||

| 100,110 | 212 | 167 | 484 | ||||||||||||||||

| MLL11-Ⅰ-630 | 4000 | 6300 | 12500 | 1200 | 80,85,90,95 | 172 | 132 | 411 | 630 | 265 | 300 | 245 | 295 | 50 | 782 | 197 | 1.8 | ||

| 100,110 | 212 | 167 | 484 | ||||||||||||||||

| MLL12-Ⅰ-710 | 7100 | 11200 | 20000 | 1050 | 90,95 | 172 | 132 | 417 | 710 | 300 | 360 | 300 | 356 | 55 | 1069 | 212 | |||

| 100,110,120,125 | 212 | 167 | 497 | ||||||||||||||||

| 130 | 252 | 202 | 577 | ||||||||||||||||

| MLL13-Ⅰ-800 | 8000 | 12500 | 25000 | 950 | 100,110,120,125 | 212 | 167 | 497 | 800 | 340 | 400 | 335 | 391 | 55 | 1920 | 294 | |||

NGCLZ drum gear coupling

The NGCLZ drum gear coupling consists of the number of teeth...

NGCLZ drum gear coupling

The NGCLZ drum gear coupling consists of the number of teeth...

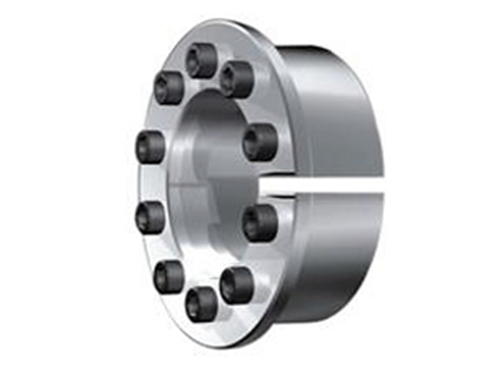

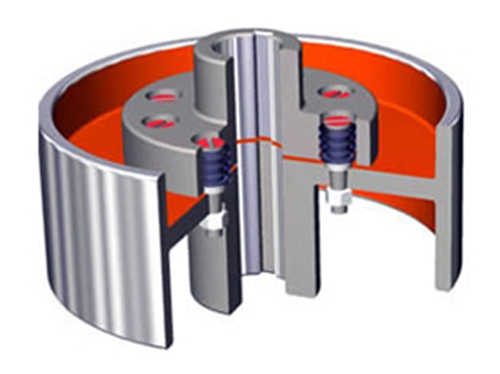

Z16 type expansion joint sleeve

The variety and quality of Z16 expansion joint sleeve...

Z16 type expansion joint sleeve

The variety and quality of Z16 expansion joint sleeve...

LZ type pin coupling

The structure of the LZ pin coupling is relatively simple...

LZ type pin coupling

The structure of the LZ pin coupling is relatively simple...

LTZ elastic sleeve pin coupling

LTZ elastic sleeve pin coupling structure comparison...

LTZ elastic sleeve pin coupling

LTZ elastic sleeve pin coupling structure comparison...