Roller chain for couplingIt uses a common chain to mesh with two parallel sprockets with the same number of teeth. Roller chain couplings of different structure types are used. The main difference is the use of different chains. Common ones include double-row roller chain couplings and single-row rollers. Sub-chain couplings, toothed chain couplings, nylon chain couplings, etc.

The advantage of roller chain coupling transmission is that it can transmit motion and power when the two axles are far apart.It can work under low speed, heavy load and high temperature conditions and dusty conditions.The transmission ratio can be accurate, the transmission power is large, and the force acting on the shaft is small.transmission.The disadvantage is that after the hinge of the chain is worn out, the pitch becomes larger and the joint is disjointed.Installation and maintenance requirements are high.The advantages of gear transmission are: the instantaneous transmission ratio is constant, the stability is high, and the transmission movement is accurate.The range of transmitted power and speed is large.The structure is compact, works, and can achieve a larger transmission ratio.Transmission and long service life.The disadvantages are: high manufacturing and installation requirements.

ZL type elastic pin gear coupling

ZL type elastic pin gear coupling is advantageous...

ZL type elastic pin gear coupling

ZL type elastic pin gear coupling is advantageous...

Z7A type locking coupling plate

Z7 type expansion sleeve is a kind of between shaft and sleeve...

Z7A type locking coupling plate

Z7 type expansion sleeve is a kind of between shaft and sleeve...

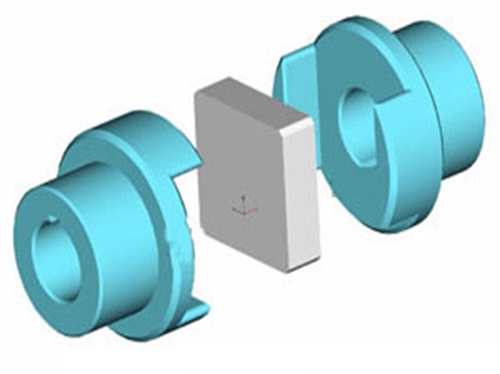

WH slider coupling

WH slider coupling and cross slider coupling...

WH slider coupling

WH slider coupling and cross slider coupling...

GⅡCLZ drum gear coupling

The GⅡCLZ drum gear coupling is made up of the number of teeth...

GⅡCLZ drum gear coupling

The GⅡCLZ drum gear coupling is made up of the number of teeth...