T type plum blossom hexagonal water pump counter wheel padThe T-shaped plum blossom hexagonal water pump counter-wheel pad is the main product produced by our company. Its quality is excellent,...

T type plum blossom hexagonal water pump counter wheel padThe T-shaped plum blossom hexagonal water pump counter-wheel pad is the main product produced by our company. Its quality is excellent,... LXJ star elastic couplingThe standard of LXJ star elastic coupling is JB/T 10466-2004.Star couplings are sometimes mistaken for...

LXJ star elastic couplingThe standard of LXJ star elastic coupling is JB/T 10466-2004.Star couplings are sometimes mistaken for... WGCI type vertical gear couplingWGCI type vertical gear coupling belongs to the category of general mechanical parts, used to connect different mechanisms...

WGCI type vertical gear couplingWGCI type vertical gear coupling belongs to the category of general mechanical parts, used to connect different mechanisms... LMD plum blossom flexible couplingThe middle elastic body of the Ever-PowerLMD plum elastic coupling closely meshes with the claws of the two half couplings and...

LMD plum blossom flexible couplingThe middle elastic body of the Ever-PowerLMD plum elastic coupling closely meshes with the claws of the two half couplings and... SWCWF flange type universal couplingSWCWF flange type universal coupling, especially the improved type (the first five types in Table 1) and other structures...

SWCWF flange type universal couplingSWCWF flange type universal coupling, especially the improved type (the first five types in Table 1) and other structures...Ever-Power Machinery Manufacturing Co., Ltd. analyzes the difference between elastic pin coupling and elastic sleeve pin coupling for you through the following points.

The difference in the appearance of the two couplings:

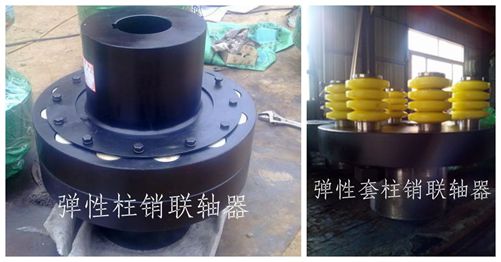

The elastic pin coupling utilizes several pins made of non-metal elastic materials, which are placed in the flange holes of the two halves of the coupling, and the two halves of the coupling are connected by the pin.

The elastic sleeve pin coupling uses a pin with an elastic sleeve (rubber material) at one end to be installed in the flange hole of the two halves of the coupling to realize the connection of the two halves of the coupling.

It can be seen that the former is to connect the two half couplings with N nylon rods, and use the baffle to fix the pins.The latter is connected by several hinged bolts, and the nut ends of the bolts are equipped with elastic washers.

The difference between the two couplings in practical applications:

1. The elastic pin coupling uses two halves of the coupling to shear the nylon rod to transmit movement and power.The elastic sleeve pin coupling uses the two halves of the coupling to squeeze the elastic sleeve to transmit movement and power.

2. The elastic pin coupling has noise during work, so please use it with caution in the working environment that requires noise.The elastic sleeve pin coupling adopts polyurethane elastic elements, which will not generate noise.

3. Compared with the elastic sleeve pin coupling, the transmission torque of the elastic pin coupling is larger, but from the comparison of comprehensive performance, the effect of the elastic sleeve pin coupling is better.