Z16 type expansion joint sleeveThe variety and quality of Z16 expansion joint sleeves are stable.The company's equipment, technology...

Z16 type expansion joint sleeveThe variety and quality of Z16 expansion joint sleeves are stable.The company's equipment, technology... Z12C type expansion joint sleeveThe Z12C type expansion coupling sleeve is suitable for the connection of the shaft and the parts on the shaft to transmit torque, axial force...

Z12C type expansion joint sleeveThe Z12C type expansion coupling sleeve is suitable for the connection of the shaft and the parts on the shaft to transmit torque, axial force... JSP type serpentine spring couplingJSP type serpentine spring coupling product features: good vibration damping, long service life, bearing variable load...

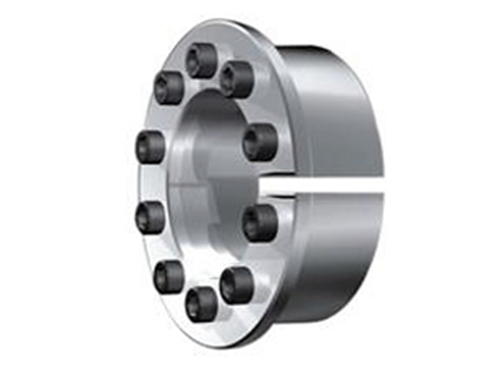

JSP type serpentine spring couplingJSP type serpentine spring coupling product features: good vibration damping, long service life, bearing variable load... Z6 type expansion coupling sleeveThe main purpose of Z6 type expansion coupling sleeve (referred to as expansion sleeve) is to replace the coupling effect of single key and spline...

Z6 type expansion coupling sleeveThe main purpose of Z6 type expansion coupling sleeve (referred to as expansion sleeve) is to replace the coupling effect of single key and spline... GY, GYS, GYH type couplingThe surface roughness of GY, GYS, GYH couplings refers to the small spacing and...

GY, GYS, GYH type couplingThe surface roughness of GY, GYS, GYH couplings refers to the small spacing and...The product must be equipped with maintenance. The same is true for couplings. The service life of coupling accessories such as elastic elements, connecting bolts, etc. has a considerable relationship with the maintenance of the coupling.Both rigid couplings and elastic couplings require normal maintenance and maintenance, so that the coupling can maintain normal torque transmission and increase the service life and indicators of the coupling, such as flange couplings, clamp couplings For the connecting bolts of the shaft, it is necessary to detect the looseness of the nut before and after the shift, and tighten the nut in time to keep the two halves of the coupling in the connected state. Of course, as a coupling manufacturer, it is good to manufacture flange couplings with protective flanges. It can protect the connecting bolt from breaking and splashing.For the same elastic coupling, attention must be paid to the bolts and elastic elements. For example, whether the elastic pin has an individual break, the gap between the elastic sleeve pin and the connecting hole of the half coupling changes, and these coupling parts should be replaced in time. On the one hand, the normal torque transmission of the coupling can be achieved, and on the other hand, the service life and performance of the coupling can be improved.Drum gear couplings should pay attention to the sealing state of the coupling while checking the bolts, that is, whether the two halves of the coupling have oil leakage. If found, replace the sealing ring in time.The diaphragm coupling is to pay attention to the integrity of the connecting bolts and the diaphragm. The connecting bolts of the diaphragm coupling bear the torque transmission function, so the bolts and the two halves of the coupling should be checked strictly while checking for looseness. If the gap is too large, you need to change the two halves of the coupling or the bolt holes of the coupling. You can increase the bolt hole with a quenched steel sleeve to make the inner hole consistent with the bolt diameter, which can improve the coupling Service life.