<XNUMX>, rigid coupling and elastic coupling

In wind turbines, rigid couplings and elastic couplings (or universal couplings) are often used.Rigid couplings are commonly used in the connection of two shafts with good alignment, while quincunx couplings can provide two shafts with poor alignment. The important thing is that the elastic coupling can provide a flexible Link, this link can absorb the extra energy generated by the fluctuation of the shafting and external load.

In wind turbines, a rigid coupling is usually used at the low-speed shaft end (the connection between the main shaft and the gearbox low-speed shaft).Generally, expansion sleeve couplings and pin couplings are used.Use elastic coupling (or universal coupling) at the high-speed shaft end (the connection between the generator and the gearbox high-speed shaft).Generally use tire coupling or ten-byte coupling.

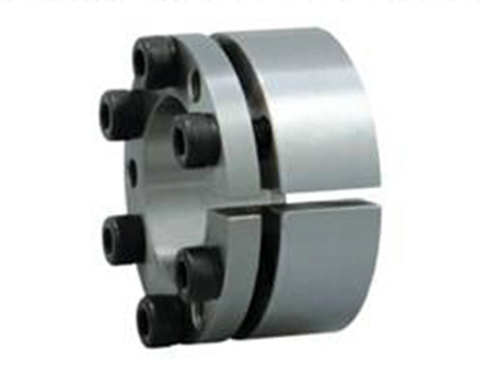

Rigid (expanded sleeve) connection is a new type of transmission connection.In the XNUMXs, the industry, such as Germany, Japan, and the United States, has widely adopted this for mechanical connections under heavy loads.Compared with general interference connection and keyless connection, expansion sleeve connection has many advantages:

①The manufacturing and installation are simple, and the processing of the shaft and hole for installing the expansion sleeve is not as required by the manufacturing tolerance as the interference fit.Installation of the expansion sleeve does not require heating, cooling or pressurizing equipment, just tighten the bolts according to the specified torque.Moreover, it is convenient to adjust, and Lun Yi can be easily adjusted to the desired position on the shaft.

②It has good interchangeability and is easy to disassemble.This is because the expansion sleeve can connect the wheels with a larger fit gap.Loosen the bolts when disassembling, and the connected parts can be easily disassembled.

③The expansion sleeve connection can bear heavy load.The expansion sleeve structure can be made into a variety of styles. One expansion sleeve is not enough, and multiple expansion sleeves can also be used in series.

④The expansion sleeve has a long service life.Because it is driven by friction, there is no keyway weakening to the connected parts, and there is no relative movement, and it will not wear out during work.After the expansion sleeve is tightened, the contact surface is tightly attached and not easy to rust.

⑤When the expansion sleeve is overloaded, it can protect the equipment from damage.

The basic requirements for flexible couplings in wind turbines are:

①, the carrying capacity is large.Since the drive shaft system of the wind turbine generator may have instantaneous peak load, it is required that the allowable instantaneous larger torque of the coupling is more than three times the allowable long-term torque.

②High elasticity, large damping, and sufficient damping capacity.Reduce the amplitude of shock and vibration to the allowable range.

③ It has sufficient compensation to meet the needs of the displacement of the two axes during work.

④ The working performance is stable, and the coupling with rubber elastic elements should also have the characteristics of heat resistance and not easy to aging.

When the crane is working, the misalignment of the coupling between the reducer and the motor of the hoisting mechanism and the luffing mechanism, or the shaft between the two due to excessive installation errors, will cause the vibration of the machine, the wear of the bearing and the shaft Deflection and deformation will cause the high-speed shaft of the reducer to break in serious cases, which poses a great threat to the normal operation of the system. From the recent several accidents of the crane reducer shaft broken, it may be caused by such factors. of.

<XNUMX> Treatment of the misalignment of the fan and motor coupling

The fan and the motor are connected by a coupling to transmit movement and torque.The main coupling types include pin couplings or couplings.Misalignment is a common failure of fans, and 60% of fan failures are related to misalignment.The misalignment fault of the fan refers to the degree of inclination or deviation between the axis line of the two rotors of the fan and the motor and the center line of the bearing.The main reasons for the misalignment of the fan rotor system:

(1) The bearing air gap is too large or the ball is slightly corroded. This situation is generally caused by insufficient lubrication or poor oil quality. This situation can easily cause misalignment and vibration. The bearing should be replaced according to the situation.

(2) Long-term vibration of the bearing seat causes deviation.Vibration of a large fan is inevitable, so it is easy to cause the base fastening bolts to loosen slightly, and the consequence is to cause misalignment and vibration.

Bearing seat installation standard: the longitudinal and transverse centerline deviation of the bearing seat is ±0.5mm.The horizontal tolerance of the bearing seat is 0.1/1000.The longitudinal levelness of the two bearing seats should then be based on the axial levelness of the rotor.The bearing seat and the base bolts should be tightly fitted after being tightened, and check with a 0.05mm feeler gauge to not be inserted.

(3) Caused by the main motor itself.Large motors have higher requirements for dynamic balance. Due to various reasons, the motor itself is damaged due to various reasons and requires misalignment.After the fan rotor system has a misalignment fault, a series of dynamic effects that are unfavorable to the operation of the equipment will be generated during the rotation process, which will cause the deflection of the coupling, the wear of the bearing, the steady state of the oil film, and the deflection and deformation of the shaft. The force and the additional force on the bearing cause the abnormal vibration of the fan and the early damage of the bearing, which is harmful.For the fan misalignment fault.

At present, we generally adopt primitive methods to deal with it.First find the level of the fan main shaft, and turn the impeller to rotate, the level deviation of the fan main shaft at each point is within the range; then find the center of the fan and the motor drum gear coupling, generally using a dial indicator, The beating degree is detected in 4 points, and the beating degree of 4 points is within the technical range, so that the middle degree is basically found.The solution can be solved with a laser alignment instrument, which is convenient.

Gear coupling GIICL typeThe gear coupling GIICL type is composed of an internal gear ring with the same number of teeth and a flange half coupling with external teeth, etc...

Gear coupling GIICL typeThe gear coupling GIICL type is composed of an internal gear ring with the same number of teeth and a flange half coupling with external teeth, etc... JMⅡJ diaphragm couplingThe JMⅡJ diaphragm coupling compensates for the misalignment of the two axes. Compared with the gear coupling, the angular displacement can be larger...

JMⅡJ diaphragm couplingThe JMⅡJ diaphragm coupling compensates for the misalignment of the two axes. Compared with the gear coupling, the angular displacement can be larger... Z3 type expansion coupling sleeveThe characteristics of the Z3 type expansion coupling sleeve: The Z3 type expansion inner and outer cone rings are tightened with inner hexagonal bolts, which can transmit more...

Z3 type expansion coupling sleeveThe characteristics of the Z3 type expansion coupling sleeve: The Z3 type expansion inner and outer cone rings are tightened with inner hexagonal bolts, which can transmit more... LMS quincunx elastic couplingLMS plum-shaped elastic coupling has, product, model, user...

LMS quincunx elastic couplingLMS plum-shaped elastic coupling has, product, model, user... Z6 type expansion coupling sleeveThe main purpose of Z6 type expansion coupling sleeve (referred to as expansion sleeve) is to replace the coupling effect of single key and spline...

Z6 type expansion coupling sleeveThe main purpose of Z6 type expansion coupling sleeve (referred to as expansion sleeve) is to replace the coupling effect of single key and spline...