FCL type elastic sleeve pin couplingFCL type elastic sleeve pin coupling has the performance of compensating the relative deviation of the two shafts, suitable...

FCL type elastic sleeve pin couplingFCL type elastic sleeve pin coupling has the performance of compensating the relative deviation of the two shafts, suitable... JMI diaphragm couplingThe JMI diaphragm coupling belongs to the JM series of diaphragm couplings that can compensate the driving machine and the driven machine...

JMI diaphragm couplingThe JMI diaphragm coupling belongs to the JM series of diaphragm couplings that can compensate the driving machine and the driven machine... Conveyor special couplingConveyor coupling is used to connect two shafts (driving shaft and driven shaft) in different mechanisms to make them...

Conveyor special couplingConveyor coupling is used to connect two shafts (driving shaft and driven shaft) in different mechanisms to make them... LX star elastic couplingEver-PowerLX star-shaped elastic coupling uses engineering plastics as elastic elements to compensate for the relative deviation of the two shafts...

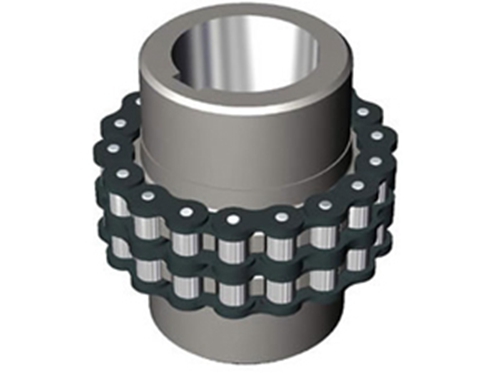

LX star elastic couplingEver-PowerLX star-shaped elastic coupling uses engineering plastics as elastic elements to compensate for the relative deviation of the two shafts... GL type roller chain couplingThe GL type roller chain coupling has a simple structure (composed of four pieces), convenient assembly and disassembly, and does not...

GL type roller chain couplingThe GL type roller chain coupling has a simple structure (composed of four pieces), convenient assembly and disassembly, and does not...The rigid coupling has good startability, which can transform the load starting of the motor into no-load transmission, realize the soft start of the working machine, reduce the starting current, adjust the transmitted torque, realize overload protection, have compensation performance, and be connected with flexibility. The shaft is matched with mechanical transmission performance.It is suitable for mechanical equipment that starts with load or frequently starts without speed adjustment, such as centrifugal pumps, blowers, air compressors, belt conveyors, scraper conveyors, mixers, ball mills, etc.The working principle and characteristics are the same as the steel ball coupling, but the structure, shape and working process are different. The steel ball type uses the rotor as the active end, and the steel sand type uses the shell as the active end. Like the steel ball type, the steel grit can be changed. The filling amount is used to adjust the transmitted torque and realize the function of overload protection.By changing different springs to adjust the sliding torque of the coupling, the impact load during starting can be partially slowed down, and it will automatically slip when the load is lifted, which plays a role of overload protection.The transverse speed, connection and running balance can not only be used for overload protection and no-load starting, but also mainly used for clutch, tension control, servo mechanism, speed regulation, test loading, commutation, etc. It is usually called a magnetic powder clutch.